In the early response to a user’s question, WorkingBear mistakenly mixed up the terms “blind hole” and “buried hole” when talking about PCBs. To prevent similar errors in the future, WorkingBear took the initiative to study some books about PCBs and clarify the concept of “vias” on PCBs.

As you may know, PCBs are made up of layers of copper foils stacked together. These “vias” are what connect different layers of circuits on the PCB. It’s similar to an underground system with interconnected tunnels. If you’ve played the video game “Super Mario,” you can think of it like the pipes that allow Mario to travel between different areas.

However, in the case of PCBs, the purpose of these connections is to allow electrical signals to flow between the copper layers. That’s why they are called “vias.” It’s important to note that the holes created by drilling or laser alone are not conductive. To enable the flow of electrical signals, a conductive material like copper is electroplated on the walls of these holes. This creates a pathway for the electronic signals to move between different layers. The original surface of the hole, which is made of non-conductive material, doesn’t allow the signals to pass through.

Now that we understand the purpose and principle of vias, let’s take a look at different types of vias. This way, we can have more effective discussions with engineers without any confusion.

There are three common types of vias that we often encounter on PCBs. They are described as follows:

Plating Through Hole (PTH):

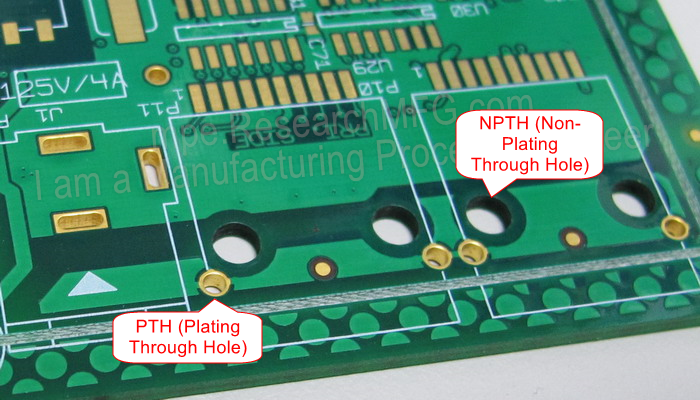

This is the most common type of via you’ll find. If you hold the PCB up to a light, you’ll see the holes that let light pass through, and those are called “plating through holes.” These holes are relatively simple to make by drilling or using lasers cut directly on the PCB. It’s a cost-effective method. However, not all circuit layers need to be connected with these through holes.

Let’s imagine a six-floor building where WorkingBear owns the third and fourth floors. WorkingBear builds a staircase between these floors but doesn’t need to connect to the other floors. In this case, creating a staircase that connects all six floors would be unnecessary and wasteful. Considering the limited space on modern PCBs, such extensive connections are generally not allowed. So, while through holes are affordable, they may take up extra space on the PCB. Through holes can be further divided into PTH and NPTH.

You can learn more about them in the article “Why are there holes on the PCB? What is PTH, NPTH and vias?“

Blind Via Hole (BVH):

A blind via is a type of connection on a PCB that joins the outer layer with an adjacent inner layer, but it doesn’t go all the way through. It’s called “blind” because you can’t see through to the other side. Blind vias are used to save space on the PCB. However, it requires careful drilling depth (in the Z-axis), and it often presents challenges in plating the hole, so it is rarely used by manufacturers now.

Alternatively, vias can be drilled individually in specific CCL layers and then bonded together. For example, in a 2+4+2 PCB, the vias can be drilled to connect the outermost two layers or simultaneously connect the 2+4 layers. This approach requires precise positioning and alignment devices.

Using our previous building analogy, if a six-floor building has a staircase connecting only the first and second floors or the fifth and sixth floors, it’s like a blind via. On a PCB, you can see the hole on one side, but it’s hidden on the other side.

Buried Via Hole (BVH):

A buried via is a type of connection between layers inside a PCB that doesn’t extend to the outer layer. It’s different from blind vias because the holes are completely hidden within the board. To create buried vias, the holes are drilled during the manufacturing process before the layers are bonded together. This process requires more effort and is more expensive than traditional vias. Buried vias are commonly used in high-density interconnect (HDI) PCBs to maximize the available space. Just like a six-floor building with a staircase connecting only the third and fourth floors, it’s similar to a buried via. You can’t see the holes from the outside of the PCB; they are buried within the internal layers.

Related articles:

- Differences, advantages, disadvantages, and recommendations for SMD and NSMD pad designs

- What is the Purpose of Surface Finishes for PCB? A Summary of the Pros and Cons of Common PCB Finishes

- How to Bake PCB? Baking Conditions and Methods, Why Expired PCBs Need to Be Baked Before SMT or Reflow Soldering?

Leave a Reply