While organizing an article on the structural analysis of Micro-USB connectors, Workingbear came across an interesting soldering concept that he would like to discuss with everyone.

During the product development and NPI verification phase, RD often comes to me, I am a Manufacturing Process Engineer, with questions about the length of the metal shell soldering pins on Micro-USB connectors. Typically, these pins are only 0.8mm long because the thickness of mobile phone boards is usually around 0.8mm to 1.0mm only. However, our company’s PCBs have a thickness of 1.6mm.

When the SMT production line use the reflow soldering process to solder the Micro-USB connector, they often find that the solder inside the through-holes of these metal shell grounding solder pins is not completely filled. In some cases, it is only about 70% filled, leaving a depth of approximately 0.3mm to 0.5mm of unfilled space. This raises concerns about the soldering strength of the Micro-USB connectors. The question is whether it is possible to request the factory to completely fill these through-holes with solder or allow the solder to protrude from the surface of the PCB to enhance the soldering strength.

What R&D question is as follows:

-

Would the incomplete filling of the through hole with solder affect the soldering strength of the Micro-USB connector?

-

Can we request the SMT factory to ensure that the solder in these holes is filled completely or allow it to protrude from the PCB surface to enhance the soldering strength?

Interestingly, it seems that whenever there is an issue with components detaching, our RD immediately approaches us (the manufacturing end) to request stronger solder from the SMT factory. It make us wonder if we are seen as easy to negotiate with, or if there is something else play?

In such cases, Workingbear usually ask the other party to bring the problematic Micro-USB connectors and PCBAs to me for inspection. Almost every time, it is discovered that the Micro-USB connector has detached from the PCB. Since our company follows a policy of conducting plug and drop tests on these connectors, there is a reliability issue that needs to be addressed.

After inspecting the detached parts and PCBA, Workingbear found that the solder on the position side of the through-hole of the metal shell soldering pin of the Micro-USB connector showed no signs of cracking. Therefore, even if the solder paste is 100% completely filled in the through-hole, and subjected to the same test, the Micro-USB connector will still detach. It is analogous to burying a utility pole in the ground and then suddenly having it blown over by a typhoon or hurricane, but attributing the issue to insufficient soil beneath the pole rather than considering the depth of the pole or the strength of the wind. The key point is due to insufficient depth of the pole or an excessively strong wind. The amount of soil under the pole should not be the issue.

So, how can we reduce the chance of the utility pole being blown over by a typhoon?

- Bury the pole deeper.

- Add other supports beside the pole.

These two points are common practices in Taiwan and other countries, and we can actually see these solutions being implemented. So, if you’re smart, you should already know how to strengthen the Micro-USB connector to withstand plug-in/out, or accidental drops!

-

Request the connector supplier to customize the length of the metal shell’s soldering pins (depth of the buried utility pole) for the Micro-USB connector. Whether the supplier is willing to customize the soldering pins to be longer for your company’s product depends on your buying force. It also depends on the thickness of your company’s PCB.

-

Use other mechanisms outside the Micro-USB connector to prevent the possibility of being pushed drop (add additional support next to the pole). The usual practice is to add an metal frame outside the original Micro-USB connector and clamp it onto the PCB, or to use other stronger components beside the Micro-USB connector to support it.

Looks like Workingbear needs to work harder. Because many people still have misunderstandings about the strength of soldering, thinking that “the more solder volume, the stronger the soldering strength” is not completely correct. The correct concept should be “soldering strength is proportional to the area of the soldering joint”. Without considering the surface finishes of the PCB and the solder paste, there are two key points to enhance the soldering strength of the components:

-

Increase the soldering contact area of the component’s terminals or leads. It is not the soldering volume! Therefore, adding a large mass of solder is almost the same as just filling the solder into the soldering pin. If you look closely, you should be able to see that most Micro-USB connector suppliers are working on the soldering pins of the metal shell, some by punching holes above the soldering pins, and others by adding creases to increase the contact area of the solder and enhance the soldering strength.

-

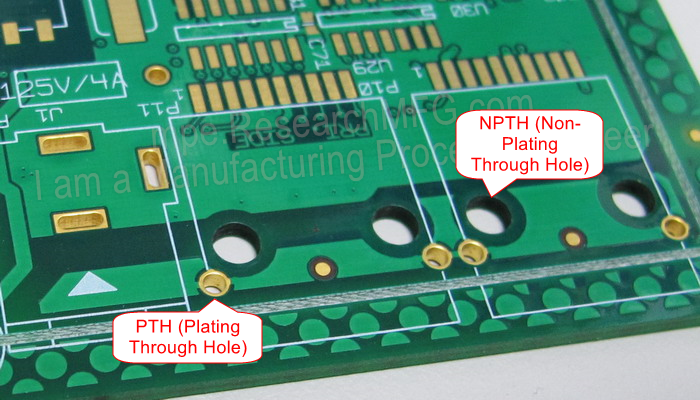

Use structural design to transfer the force to other mechanisms to bear. The most common design is to make the pins of the Micro-USB metal shell from SMD type to upright and perforated, so that the force can be transferred to the wall of the PCB hole to bear.

This article translate from 電子零件焊接強度的觀念澄清

Related Articles:

What Process Impact of Substituting SMDs with Paste-In-Hole components?

Why BGA soldering ball always crack(5)? Increase the contact area of solder to increase its strength

Leave a Reply