This story is long-standing memory, but WorkingBear is documenting it here for reference and as a learning record.

One day, we received a customer complaint regarding a product with a plastic housing that had cracked. The issue was visually striking, with noticeable cracks on the outside of the plastic casing. The situation called for immediate investigation.

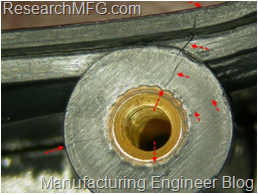

After examining several defective plastic parts, we discovered that all the cracks were located at the screw boss area. The cracks extended from the inside of the plastic housing outward. Interestingly, the screw boss was designed with a mold-in screw insert, which had been installed during the injection molding process. Based on our initial analysis, it appeared that the issue could be related to the screw boss mechanical design or the injection molding conditions.

To help others facing similar issues (and to serve as a personal memo), WorkingBear has compiled a list of potential causes for screw boss cracks for reference.

1. Using Regrind Resin

Mixing regrind resin with virgin resin during the injection molding process can degrade the mechanical properties of the final plastic product.

To evaluate whether regrind material has been mixed with virgin resin, we commonly use the MFI (Melt Flow Index) value as an indicator. From experience, the MFI value of molded plastic materials (resin that has already undergone at least one injection process) typically increases by approximately 25-30% compared to virgin resin.

If virgin resin is mixed with regrind resin and used in injection molding, the resulting MFI value often exceeds the original value by more than 30%. This increase in MFI suggests a degradation in the material’s quality, as higher MFI values generally correlate with reduced viscosity and potentially weaker mechanical properties.

Recommending Post: Understanding Melt Flow Index (MFI) for Quality Control in Plastic Injection Molding

2. Screw INSERT Without Pre-heating

Experience shows that screw inserts shall be preheated before being placed into the injection mold. Preheating help reduce internal stress and prevents the cold insert from damaging the plastic screw boss due to thermal expansion and contraction during molding.

Imagine a scenario where a copper material of insert-part is placed into the mold at room temperature (about 25°C) and then exposed to the high temperatures of the molding process, often reaching around 300°C. As the insert heats up, it expands. However, by the time the mold begins to cool and the plastic resin starts to solidify, the insert may still be expanding. This mismatch between the swelling of the insert and the shrinking of the surrounding plastic creates internal stress. If this stress exceeds the strength of the plastic resin, cracks will likely form at the interface between the insert and the plastic boss.

3. Impact of Plastic Molding Parameter

The molding parameters also play a crucial role in preventing cracks. For example, using lower packing pressure and shorter packing times can reduce internal stress around the screw boss, minimizing the risk of cracking. However, this comes with trade-offs—lower packing pressure can lead to sink marks in thicker sections of the plastic and may reduce the mechanical strength of the part. Finding a balance in the molding parameters is essential to ensure both durability and cosmetic quality.

4. Design Considerations

According to design guidelines, such as those outlined in DuPont’s “Molded-In Inserts: Precautions and Guidelines,” the diameter of the molded screw boss should be at least 1.5 times the diameter of the insert. For inserts larger than 12.9mm (0.5”), this guideline becomes even more critical. Thicker boss walls can lead to increased stress around the insert due to thermal expansion during heating and contraction during cooling, which echoes the reasons described in the preheating section. Proper design of the boss wall and insert dimensions can significantly reduce the risk of stress-induced cracking.

Backup Plan:

To address the issue of screw boss cracking, we implemented a two-pronged solution finally:

-

Short-Term Fix: Preheating the insert parts before plastic injection. This minimizes internal stress caused by the thermal expansion mismatch between the cold insert and the surrounding plastic.

-

Long-Term Fix: Redesigning the part to enlarge the inner diameter of the plastic screw boss. This reduces stress concentration and provides better structural support for the insert.

For more details about this case, refer to the related post: Case study for the mold-in insert screw boss broken

This article translates from https://www.researchmfg.com/2013/01/mold-in-screw-crack-potential-cuase/

Related Posts:

Hi

I was looking for some reference online to trouble shoot a problem which i am facing when i chance upon your site.

I currently have a plastic housing that uses PC with glass fill 9% and has 4 mold in screw insert. the problem i have screw boss cracking and breaking. I will say put it as 2 “issue” as the crack propagate from the center towards the circumference and they are vertical. very similar to Hoop stress crack. secondly I have screw boss “shearing” off at the base of the insert , at half the boss height. After reading some reference and guide, i will say the first is due to hoop stress or poor insert quality which causes the boss to burst. the second failure , iam not sure as it may not have or usually do not have any crack. it just pops out after some time in a complete product. meaning there are axial stress constantly. hope you can offer some insight to what maybe causing this? i am guessing its material degradation, or sharp points on the insert.

HC,

1. You shall know this kind of screw insert boss broken was caused by stress.

2. If your inset is mold-in process then you must check the item 4, to review the plastic screw boss diameter and insert parts diameter. Too much diameter of plastic screw boss will bring crack. I finally reduce the diameter of plastic screw boss then fix the problem. The stress will gradually make the plastic broken after couple weeks in a complete product.

3. If you suspect plastic resin quality then you can check the MI (Mold Index) Value or call as MFI. Usually the MI value of complete product shall be less than 1.3 times of original value. As I knew that plastic supplier will add 20% of the re-grind resin. If this is true then the complete product MI value shall be less than 1.5 times of original value.

Hi WorkingBear, Do you think the shape and sharp edges of the insert plays a part too? my current insert does not have chamfer or rounded edges. the break seems to start from the edge of the insert.

HC,

Well, Only if your screw insert parts apply ultrasonic to be pressed into the plastic boss. Otherwise I didn’t see the sharp edges of the insert will contribute the breaking. If you use ultrasonic press in then the chamfer must be designed on press in direction to make insert parts easily be pressed in without too much obstruction.

May I know what is your process to put this insert into plastic boss? there are many solutions (ultrasonic, heat-staking, mold-in) can reach it and every solution has different requirements.

Hi WorkingBear, we are currently doing molded in insert. the wall of the boss is 0.7mm for an insert with 2.4mm diameter. Initially we were thinking that by increasing wall thickness we might solve the issue, but now i am unsure as it seems it will get worse for circumferential stress

Here is my case. My original design show the boss diameter with 7.16mm for an insert with 2.38mm diameter.

If your boss will be crack after screw then I do think you may need to increase boss diameter. If your boss crack without any screw then you may refer to my case below.

Here is my case, the original boss diameter is 7.16/2.38=3.0 times the insert diameter and parts stored in warehouse over one week then found the crack without final assembly. The crack was terrible and it broken from inner boss to outside wall of plastic. I highlighted this issue to plastic supplier and asked them to do pre-heat for the insert parts before put it into the tooling. Thanks god the crack be fixed. That means there really something wrong in plastic supplier side but I can’t and hard to prove it.

I finally change the design and reduced the boss diameter from 7.16mm to 5.25mm (considering the draft angle) and added radius on all core side and remove the pre-heating requirement for the insert parts. I was thinking the proposal of 1.5 times from design guideline is really small and would like to do the tool modification step by step gradually and not reduce it to 1.5 times at one time. Now 2 years pass and I never heard boss crack issue for this case.

So. I will not say you can’t increase your boss diameter since your wall thickness is 0.7mm only. I do recommend you shall ask your plastic supplier why crack happen and make a QA plan to do screw torque test for the plastic parts. By the way, my plastic resin is PC and shall have more strength ability.

We also appear the same issue, please comment for us how about temperture pre-heating for insert before moulding ?. (We used plastic PC resin)

Manhkv,

You can refer to this article https://mpe.researchmfg.com/case-study-mold-in-insert-screw-boss-broken/