We recently encountered a soldering issue with a DDR memory BGA (Ball Grid Array). The problem identified was HIP (Head-In-Pillow) — two balls with non-wetting under the BGA package were affected. To investigate, we sent someone to the field to assess the customer’s operation, discovering that the product failed to power on. Interestingly, applying finger pressure to the DDR memory component would successfully power it on.

Why did this occur? The production line claimed the products underwent a 12-hour power-on Burn/In (B/I) process at 40°C but didn’t screen out the defect. So, why did we still observe this type of BGA soldering defect in the field?

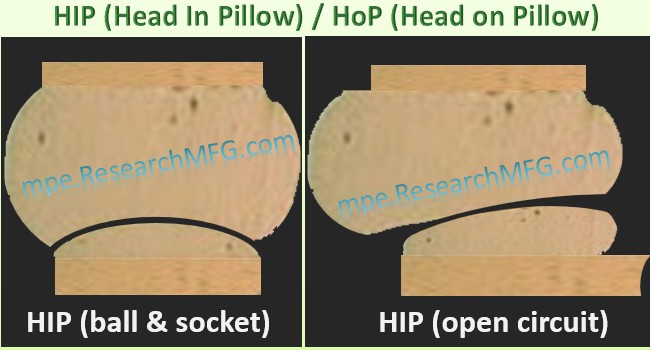

Before addressing this, let’s understand how the HIP defect occurs. HIP is a solder joint defect where the solder paste wets the pad on PCB but doesn’t fully wet the ball on BGA. This is typically caused by the deformation of PCB and BGA substrate during high-temperature reflow. The deformation separates the solder paste on the pad and the ball on the BGA while the solder is in a liquid phase. As the parts cool down and the deformation gradually returns to normal, the liquid solder solidifies, resulting in two balls becoming HIP.

HIP is a significant reliability and quality concern that can adversely impact brand credibility. The conventional board-level tests (ICT, FVT) struggle to detect HIP defects effectively. Consequently, these defects often bypass the production quality checks and reach the end customer. It’s only a matter of time before such defects are identified, leading to eventual returns for repairs.

Why can’t factories identify DDR soldering failures even with Burn/In (B/I) implementation and 100% functional tests?

It’s a puzzling issue. Based on my personal experience, here’s a speculative explanation:

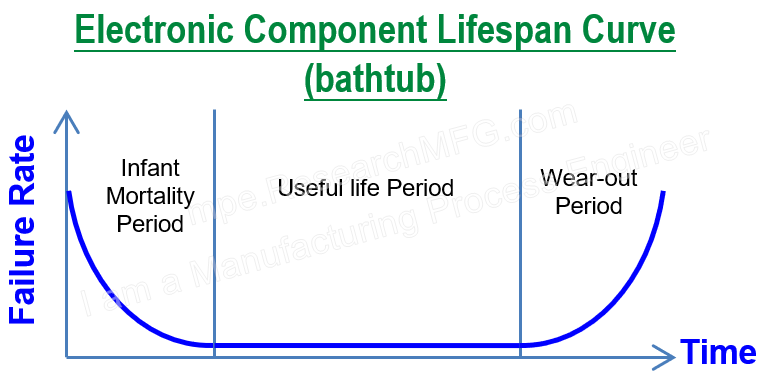

Consider when the HIP defect might manifest as a circuit open. It seems most likely to occur when the product is powered on, electronic components start running, and the PCB and BGA begin to heat up. If the product is turned off, it stays at a lower temperature, causing slight deformation in the PCB and BGA. The two balls may then form a faulty contact. When the product is powered on again and heats up due to electronic components generating thermal energy, the deformation worsens, leading to an open contact between the two balls and resulting in a functional failure.

Now, let’s explore reasons why Electronics Manufacturing Services (EMS) might struggle to identify DDR BGA failures:

-

Products undergo Burn/In (B/I) but are not powered on for a self-diagnostic functional test. This often occurs in EMS scenarios where only PCB Assemblies are produced without box builds. The product is typically powered on from a lower temperature, cools down after testing, and is then powered off.

-

Products undergo Burn/In (B/I) and are powered on but do not undergo diagnostic tests to run DDR tests. Certain DDR soldering issues may not affect the product’s power-on phase; the problem might only manifest when it runs to a specific memory address, revealing an error.

-

Products undergo Burn/In (B/I) and are powered on for diagnostic testing. Some DDR function test failures may disappear upon repowering. It is advisable to have a program automatically record error messages during diagnostic tests to help operators and technician check for any errors in the product.

Therefore, if products undergo Burn/In (B/I) but lack a well-designed program for diagnostic testing and error message recording, HIP soldering issues may not be easily screened out 100%.

Related Posts:

- SMT Reflow Soldering Temperature Profiles Explanation and Precautions

- Preventing BGA Solder Joint Cracking: Strengthening Design from the Source

- Preventing Solder Cracks in BGA Designs: Strengthening Tips from the Design End

- Questions from Newcomer: Why is Solder Paste Needed for SMT Reflow since BGA Already has Solder Balls? Is Solder Paste

Leave a Reply