What is the difference between PCB and PCBA? This should be an easy concept to understand, but since someone asked Workingbear, let’s explain it a bit. If you find any errors while passing by, please let us know to correct them.

Most people have probably heard of the term PCB. If you follow financial news, YouTube or read related articles, you might have come across this term. However, for those not in the electronics industry, the term PCBA might be less familiar, and sometimes it gets confused with PCB. Even though PCB and PCBA differ by just one letter, there is a significant difference between them in the electronics manufacturing industry.

What is a PCB (Printed Circuit Board)?

PCB stands for “Printed Circuit Board.” Some people also call it “PWB” (Printed Wire Board), a term used more commonly in some countries, but in Asia, it’s almost always referred to as PCB.

The manufacturing of a printed circuit board is somewhat like printing a book. Using film, light is projected onto a negative, and then chemical etching is used to print the copper circuits onto a hard board. With technological advancements, PCB manufacturing has become more precise and complex, but the basic printing process remains.

If you’re interested in PCB manufacturing, you can refer to this article: [Video] Introduction to PCB Production Process.

Modern electronic products have so many functions mainly because they are composed of numerous electronic circuits and components. These circuits need a carrier, which is the PCB. So, a PCB is essentially a board with printed electronic circuits that must support electronic components, such as resistors, capacitors, inductors, ICs, and connectors, without losing functionality. It also provides the communication pathways between components. If we think of the earth as the carrier, electronic circuits are like the roads connecting towns, and the PCB is the land filled with roads, with electronic components being the towns and cities.

So, what’s the role of a PCB? It’s like a piece of land that has been planned and laid out, just waiting for various functional components to be installed in specific locations. When all the electronic components are assembled onto the PCB, it becomes a PCBA. Now, you should have a general idea of the difference between PCB and PCBA.

We call a PCB that has the electronic circuits printed on it but has not yet had components assembled onto it a “blank circuit board” or “bare board,” to distinguish it from a PCBA. It’s easy to confuse the two since they differ by just one letter.

A PCB is one of the most crucial components in the modern electronics industry. It supports electronic components and provides the electrical connections between them. While flexible printed circuits (FPCs) can also serve as carriers, they have specific applications and requirements that differ from rigid PCBs. In most electronic product designs, rigid PCBs are predominantly used.

To put it simply, the PCB is like the engine of the electronics industry because almost all electronic devices need it. However, the PCB manufacturing process involves electroplating, which requires large amounts of water and electricity and can cause water pollution. With the rise of environmental awareness, the costs have significantly increased.

In Taiwan, there are many companies that produce PCBs and IC substrates, such as Zhen Ding, Unimicron, Compeq, Chin Poon, Nanya PCB, Gold Circuit, Nan Ya Plastics, and Yaohua, to name a few. Of course, there are many other companies not listed here. The assembly of PCBA is usually completed by system manufacturers or EMS (Electronic Manufacturing Services) providers. Besides their own assembly plants, these include Quanta, Foxconn, Compal, Kinpo, Pegatron, and Wistron, among others. Additionally, there is an entire upstream industry for PCBs, including copper-clad laminates, insulating films, reinforcing plates, solder masks, and adhesives, among others, involving a long list of related companies.

The Unique Features of PCB That Have Led to Its Widespread Use in the Industry

-

High Wiring Density, Small Size, and Light Weight: These characteristics support the miniaturization of electronic products. Recently, PCB density has been approaching early integrated circuit technology, and some manufacturing processes are gradually adopting semiconductor equipment.

-

High Reproduction Stability: PCBs can be mass-produced with high repeatability and consistency, reducing the likelihood of wiring assembly errors compared to using cables. Modular design enhances maintenance, debugging, and inspection efficiency.

-

Automation Capability: PCB and PCBA production can be almost fully automated, reducing labor costs and operational errors, and increasing productivity, which helps lower product prices and expand market reach.

-

Standardized and Modular Design: PCBs can be standardized or designed as modules. For different functions, you can simply replace the entire PCBA board.

What is PCBA?

The difference between PCB and PCBA is that “PCBA = PCB + Assembly.” A PCB without assembled electronic components is called a PCB, while a PCB with assembled electronic components is called a PCBA.

Using the earlier analogy, a PCB is like land with roads but no buildings, while a PCBA is land with roads and buildings.

PCBA stands for “Printed Circuit Board Assembly,” and some people refer to it as PCA. It is also known as PWA (Printed Wire Assembly). If there’s only one board in a final assembly device, it’s often referred to as the “Main Board.” If there are multiple PCBAs, they are distinguished by their functions, such as the main board, IO board, display board, or charging board.

How Are Electronic Components Placed on a PCB to Form a PCBA?

The mainstream method for PCBA assembly today is Surface Mount Technology (SMT). This process involves printing solder paste onto the bare board, then placing electronic components onto the PCB. The board is then passed through a high-temperature reflow oven, which melts the solder paste and secures the components to the PCB.

The mainstream method for PCBA assembly today is Surface Mount Technology (SMT). This process involves printing solder paste onto the bare board, then placing electronic components onto the PCB. The board is then passed through a high-temperature reflow oven, which melts the solder paste and secures the components to the PCB.

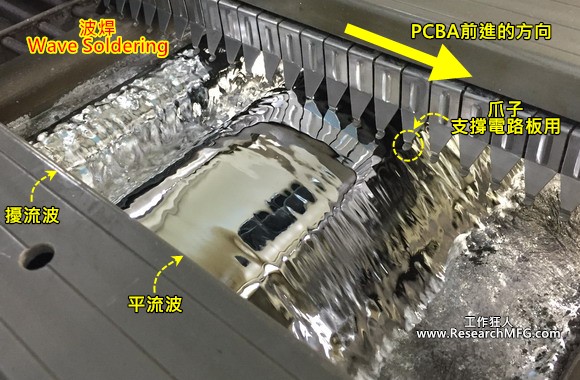

A less common method is Wave Soldering. This technique is typically used for heavier components or those that need to withstand physical stress, which are often through-hole devices (THD). These components either cannot be made as surface mount devices (SMD) due to technical limitations, or making them as SMDs would be cost-prohibitive. During wave soldering, these components are soldered to the PCB by passing the board over a wave of molten solder.

Some designs use a combination of both SMT and wave soldering to achieve the necessary component attachment to the PCB.

Conclusion

After this explanation, you should be able to clearly distinguish between a PCB and a PCBA. A PCBA can be considered a finished good, as some factories produce and sell PCBAs directly, such as standalone computer motherboards and video cards. On the other hand, a PCB is essentially a component. It is a critical part of the overall PCBA but cannot function as a PCBA on its own. Only after integrating other components like ICs, resistors, capacitors, inductors, and connectors does a PCB become a completed product. Therefore, a PCB should be regarded as one of the essential components.

Related Posts:

Leave a Reply