A Bill of Materials (BOM) is a list of materials required for the production of an electronic product. It serves as an important bridge between the designer, manufacturer, and supplier. The BOM includes all the components, devices, and materials used in an electronic product, with information such as their type, model, quantity, manufacturer, and supplier listed.

In essence, we can think of the BOM as a recipe for cooking, though it might not include the cooking steps, which are the Standard Operating Procedures (SOP). In theory (emphasis on theory), just having the ingredients and cooking instructions should allow us to prepare a dish. Similarly, in mass production manufacturer, having the BOM and SOP should enable the production of consistent products.

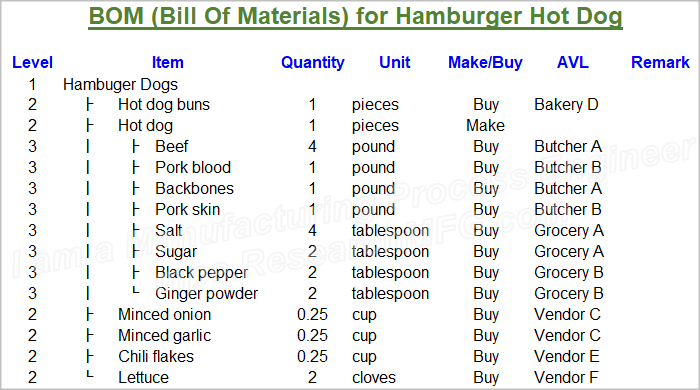

To better grasp the significance of a BOM, let’s use the analogy of making a hot dog. Firstly, apart from the need for bread, lettuce, chopped onions, and chili flakes, the star of the show is the hot dog itself. When it comes to the hot dog, you have the option to either buy a ready-made one or make your own. If you prefer making a hot dog from scratch, the primary ingredient is the sausage, which involves various materials and components such as pork, beef, pork blood, backbones, pork skin, salt, sugar, black pepper, ginger powder, etc. These materials and components are equivalent to the BOM for a hot dog. They need to be mixed in the correct proportions and quantities to create a delicious hot dog.

Each component in the BOM has unique characteristics and attributes. Just like the pork and beef used in making a hot dog have different tastes and textures, different electronic components also have different performance and characteristics. They need to be selected according to different requirements and customer demands.

In addition, the BOM also needs to list the quantity and supplier information of each component. Just like knowing the proportion and quantity of each material in making a hot dog, the quantity of each component also needs to be accurately calculated in electronic product production to ensure accuracy and efficiency in the manufacturing process. The choice of supplier is also important, as different suppliers may have different prices, quality, and delivery times, which need to be carefully evaluated and compared to select the best one.

In summary, a BOM is a crucial element in electronic product production, containing all the necessary information about components, devices, and materials. By developing an accurate BOM, it can ensure accuracy and efficiency in the manufacturing process and help select the best suppliers.

Related Posts:

Leave a Reply