When developing a new product, it is common to conduct a “trial run” to obtain a prototype sample. This serves two purposes: firstly, it allows developers to further test and validate the prototype’s functionality, and secondly, it helps the manufacturing factory understand the production process and prepare for mass production. Feedback and suggestions based on the prototype’s test results are provided by various departments involved.

In general, the manufacturing side contributes insights regarding DFM (Design For Manufacturing) and production-related aspects to ensure that the product’s design, while impressive in functionality and appearance, can be efficiently manufactured. Other departments, such as Design Quality (DQ), provide feedback on the results of functionality verification tests, and the market maintenance team may offer suggestions regarding areas that could pose challenges for maintenance purposes.

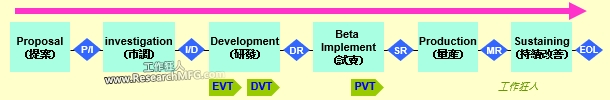

During the process of developing a new product, there are typically three stages of verification for trial run. Each stage can be further divided into multiple iterations, such as EVT1, EVT2, and so on, or they can be skipped depending on the specific needs. It’s crucial not to engage in trial run without a clear purpose or necessity, as it can lead to wastage of both time and money. For each trial run stage, the presence of engineers from the research and development and manufacturing teams is essential for on-site support. If trial run takes place in an outsourced EMS (Electronic Manufacturing Services), it can add complexity, requiring coordination with the production line and incurring additional costs.

Now, let’s delve into the three stages commonly known as EVT, DVT, and PVT in the context of new product trial production. While different companies may use varying terminology, the overall concept remains similar.

EVT: Engineering Verification Test Stage

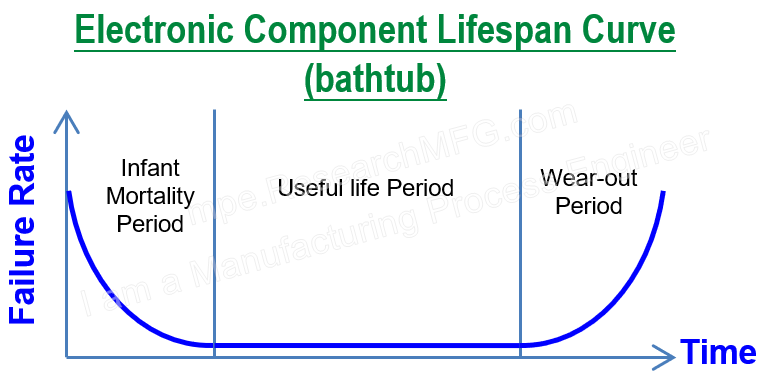

During the product development process, there are three key verification stages, and the first one is EVT (Engineering Verification Test). In the EVT stage, large circuit boards called “Big Boards” are produced as prototypes. These boards serve the purpose of testing and debugging hardware circuit designs. It’s fascinating to think that these early-stage printed circuit boards can eventually become sleek smartphones or electronic devices.

When developing a completely new product, especially during the initial design phase, there are usually many challenges to overcome. The EVT stage may require multiple rounds of trial run, depending on the progress of the development. It’s crucial to allocate enough time and resources to provide sufficient samples for the engineers to validate their ideas. However, it’s important to note that each EVT iteration comes with significant costs, so if all issues can be resolved in the first EVT round, there is no need for further iterations.

For idea validation, some companies use the concept of Proof of Concept (POC). This is more commonly associated with software development but is also applicable to hardware development. Conducting a POC before or during EVT can help clarify the feasibility of the product’s theory before investing extensively in research and development.

If the design involves modifications to an existing product, the EVT stage is generally simpler as there are fewer new technologies involved. In some cases, EVT can even be bypassed, and the project can proceed directly to the next stage.

In summary, the primary focus of EVT is to address any design issues and ensure the feasibility of the product while checking for any overlooked specifications.

DVT: Design Verification Test Stage

This is the second phase of the development process, where all the design ideas should have been confirmed. Now it’s time to add the mechanical enclosure and ensure that the printed circuit board (PCB) is sized correctly to fit inside.

During this stage, the mechanical enclosure may start as a sample or mockup made from a large piece of resin carved using a laser or produced with soft molds. With advancements in technology, 3D printers can now be used to create the mechanical structure. The goal is to validate the enclosure design before investing in expensive production molds. This step is crucial because molds can be costly, and it’s important to make sure everything is in order before moving forward.

The main focus of the DVT stage is to test the functionality of the entire device. The aim is to identify any design or manufacturing issues and ensure that all aspects meet the required specifications for mass production.

PVT: Production Verification Test Stage

Before reaching this stage, all the necessary design validations should be completed. At this point, any design-related verifications should be finalized, and it’s generally not advisable to introduce further design changes, except for those prompted by market feedback or post-production improvements.

The main objective of the PVT stage is to conduct extensive manufacturing process tests prior to mass production. This entails producing a significant quantity of products. All components should be manufactured using official molds or production tools, moving away from the manual craftsmanship employed during the EVT stage. Furthermore, the production procedures on the assembly line must adhere to established manufacturing standards, ensuring a seamless and uninterrupted production process

Additionally, it’s crucial to assess the quantity of assembly jigs, testing fixtures, and production equipment to ensure they can handle the capacity requirements of mass production.

However, the development process of a new product is not limited to just “trial run.” It encompasses several stages, including proposal, market investigation, research and development, beta implement (trial sales), mass production, sustaining, and end of life. While trial run is a crucial part of the research and development phase and receives significant attention due to its involvement of multiple individuals.

Postscript:

Additionally, different companies may use various names for trial run, such as SR/ER/PR, C0 to C6, or simple A-Run/B-Run/C-Run, and so on. However, the overall concept remains the same, and the steps and methods employed are similar.

Related Articles:

Leave a Reply