Questions from a newcomer about electronic manufacturing assembly process: Since there are already solder balls locate on the BGA substrate, why is it necessary to apply solder paste on the PCB pads during SMT reflow? Is it necessary to apply solder paste during BGA repair? And how should we apply solder paste to the corresponding pads on the BGA when there are other electronic components around the BGA?

Question 1: Since there are already solder balls on the BGA substrate, why is it necessary to apply solder paste on the PCB?

The answer to this question depends on whether it is for repair/rework or normal SMT production. In regular SMT production, the PCB is conveyed on a production line, and during the process of pick-and-place, the board may move quickly. The sticky solder paste can help to pre-fix the electronic components on the PCB, preventing them from shifting or falling off. However, for repair/rework that is done manually, the PCB may not need to be moved frequently, or the BGA can be manually pre-fixed on the PCB, so solder paste may not be necessary.

Of course, in addition to pre-fixing the electronic components, there are also other advantages to applying solder paste when soldering a BGA, such as:

-

It can improve the wetting and soldering effects. In principle, the solder balls of BGAs have already undergone at least one time of reflow, so there is basically no flux inside the solder balls. When we want to solder the BGA to the PCB, if there is a lack of flux to remove the oxide on the metal surface, the wetting of the soldering will be greatly reduced.

-

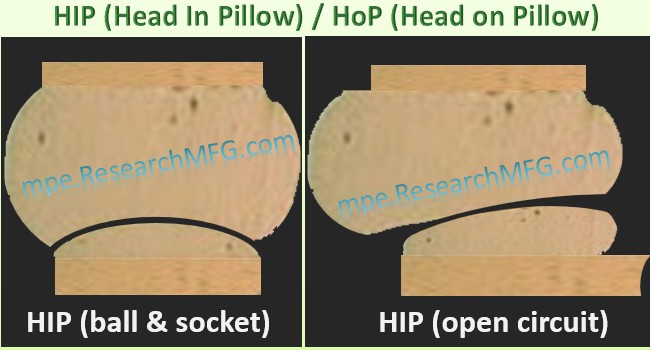

It can ensure the quality and reliability of the solder joints. BGAs are grid array packages composed of multiple solder balls. If the coplanarity of the solder balls cannot be kept completely consistent during soldering, it will cause problems such as larger solder balls being soldered to the PCB pads while smaller ones cannot effectively contact the PCB pads, resulting in issues like voids, cold soldering, and false soldering. The thickness of the solder paste can fill the height difference between the uneven solder balls, ensuring that each solder ball can be soldered to the PCB pad, improving the quality and reliability of BGA soldering.

-

It is possible to ensure consistency in soldering. The actual melting point of the tin balls on the BGA is slightly higher than that of fresh solder paste, because the solder material that has been re-melted may have mixed with the surface metal on the pad of BGA substrate, causing slight changes in the alloy composition. For example, tin-gold, tin-copper, or tin-silver IMC compounds may be mixed in the tin balls.

In addition, the surface of the tin balls does not have the protection of a flux, and after being placed in the atmosphere for a period of time, it is easy to generate a dull oxide tin film on the surface. This layer of oxide film lowers the surface energy of the tin ball and hinders soldering. During reflow, a higher temperature or the use of flux is required to remove the oxide film and enable soldering. This is one of the reasons why flux is added to solder paste.

Question 2: Do we need to apply solder paste when repairing BGA? How to apply it?

In order to ensure the BGA soldering effect and quality during repairs, we generally recommend applying solder paste on the PCB pads of the BGA. During repairs, other electronic components have already been soldered onto the PCB around the BGA, so we cannot use a standard stencil for SMT operation. Instead, we need to manually apply the solder paste on a small “rework stencil” that fits the size of the BGA (which can be found by searching for “BGA rework stencils” on “Google ” or “Baidu”), and then heat it up for reflow.

Most of the maintenance technicians in the industry think that manually printing solder paste is too much of a hassle. They are mostly daring and skilled, and since the product is not their own, it doesn’t matter much if they break it. They simply close the case by telling the customer that the board is faulty.

During repairs, after removing the excess solder on the PCB pad, a layer of flux is directly applied on the pad, and then the BGA with pre-installed solder balls is aligned and heated directly with a hot air gun for soldering. This method has a very low cost, but it also has a high failure rate and requires a lot of experience and skill. In addition, there are many quality concerns:

-

Firstly, the temperature during heating cannot be evenly distributed, making it difficult to ensure that the soldering is not warped., and the warped area of the PCB or BGA is prone to solder cracking.

-

Secondly, the hot air gun heating uses a higher temperature (about 350°C, while the maximum temperature of the reflow oven is generally set at 250°C) and cannot control the temperature applied to the BGA and PCB, which can easily cause damage to the components or PCB or reduce their service life.

-

Thirdly, manually applying flux cannot control the amount used. Flux residue on the PCB can cause corrosion over time.

So, the key points of the above two questions can be summarized as follows: metal alloy soldering material is a must-have for soldering, but to achieve good soldering results, it is necessary to use flux to remove surface oxides from the soldering material. Additionally, paste solder is used to pre-fix electronic components to PCB before reflow.

Related Articles:

Leave a Reply