Workingbear has noticed that many people still have questions about EDX/EDS elemental analysis reports. This is the second article where he tries to provide answers based on his knowledge.

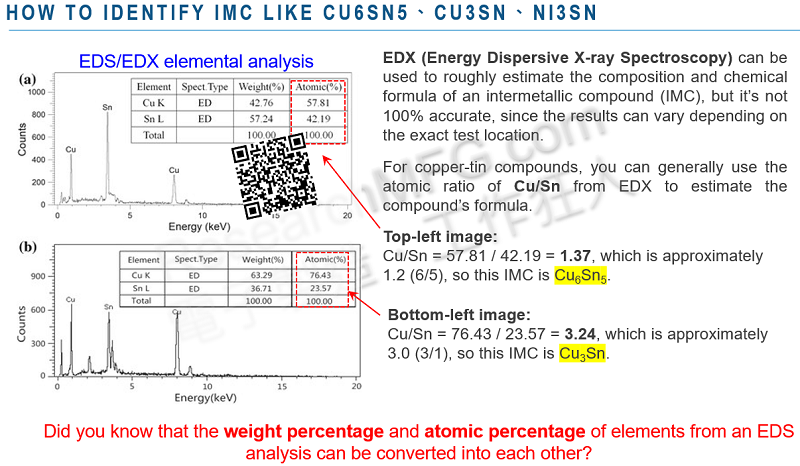

EDX (Energy-Dispersive X-ray Spectroscopy), also known as EDS, is actually an auxiliary function used in SEM (Scanning Electron Microscopy), TEM (Transmission Electron Microscopy), and STEM (Scanning Transmission Electron Microscopy) analysis techniques.