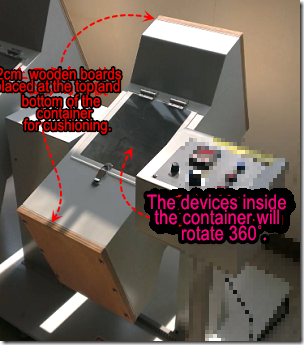

From what I remember, one of the earliest and most frequent requests for tumble testing came from Motorola. Since some of Motorola’s mobile phones and products were designed for military use, their reliability and quality standards were exceptionally strict. However, this also meant higher design and production costs. I can’t help but wonder if this was one of the reasons Motorola eventually lost its competitive edge.

Workingbear strongly believes in maintaining high-quality standards, but over-engineering beyond practical use (over quality) can be a waste of resources. Take smartphones as an example—most people replace their phones every two years. Designing a phone to last five years is already impressive. Insisting on a 10- or 20-year lifespan might only make sense if it doesn’t significantly increase costs. Otherwise, companies need to seriously consider whether the extra investment is worth it.