All materials actually have its shelf-life, some shorter and some longer than others. So what happens when expired materials are used? Think about what will happens when you eat expired food. What about using expired Printed Circuit Boards (PCBs)?

Before answering the question of using expired PCBs, we need to ask, what is the function of a PCB? What processing is required in an electronic assembly factory?

The main function of a PCB is to act as a carrier for electronic components to transmit electronic signals. If components cannot be soldered onto the PCB or contact points cannot effectively transmit electronic signals, it will affect the functionality of electronic products or cause intermittent malfunctions.

So how are electronic components soldered to the PCB?

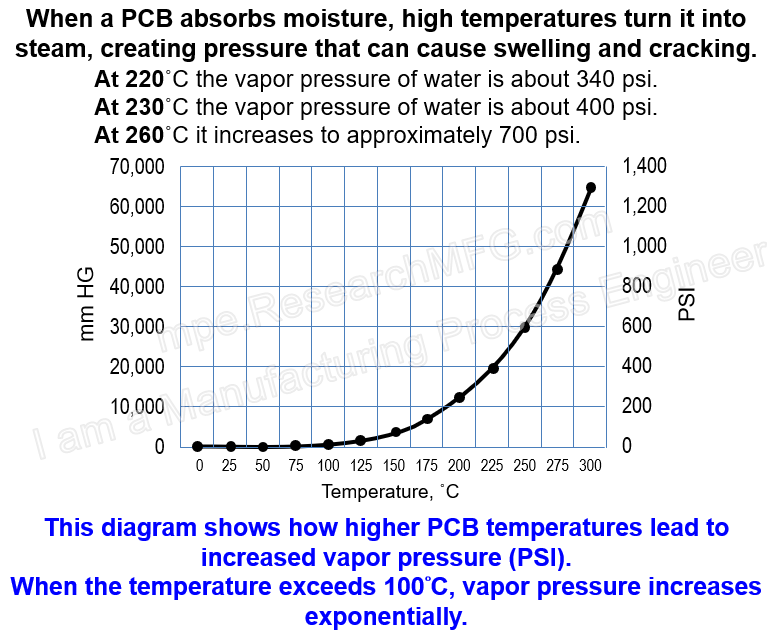

Nowadays, the PCB soldering process almost always uses high temperatures of around 240-250°C to melt the solder (solder paste or wire) and connect the electronic component pins to the PCB, so the question arises: can expired PCBs withstand at least two high temperatures of 250°C or more without any problems? The reason for mentioning two times of high temperatures is that the current PCBA process is mostly a double-sided soldering board.

Based on the above understanding, we can now see what could happen when using expired PCBs. The following problems may not necessarily occur, but there is a risk. Therefore, if you still want to use expired PCBs, you must clarify that the following issues will not occur:

Overdue PCBs may cause oxidation of solder pads

Once the solder pads are oxidized, it can lead to poor soldering, ultimately resulting in functional failure or the risk of component detachment. Different surface metal finishes for circuit boards have varying effects on oxidation resistance, with ENIG requiring use within 12 months and OSP within 6 months, with some OSP even requiring use within 3 months. It is recommended to follow the PCB manufacturer’s shelf life instructions to ensure quality.

OSP boards can generally be sent back to the PCB manufacturer to have the OSP removed and a new one applied, but there is a risk of damaging the copper foil circuits during OSP acid removal, so it is best to consult with the PCB manufacturer to confirm whether OSP can be reprocessed.

ENIG boards cannot be reprocessed, and it is generally recommended to undergo “baking” and then test solderability for any issues.

Overdue PCBs may Cause Popcorn Effect due to Moisture Attack

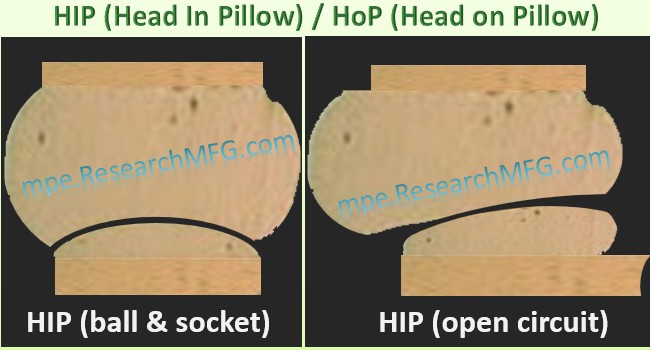

Moisture inside PC boards during reflow soldering may cause issues such as popcorn effect, board failures, or delamination. While baking can resolve this issue, it is not suitable for all types of boards, and it can cause other quality problems.

In general, it is not recommended to bake OSP boards, as high-temperature baking can damage the OSP film. However, some have tried baking OSP boards, and the baking time should be as short as possible, and the temperature should not be too high. After baking, the board must pass through the reflow oven in the shortest possible time, as baking OSP boards can easily cause oxidation of the solder pads, affecting the soldering quality. It is recommended to test bake a small batch and confirm the soldering quality before proceeding with a large batch, as the cost may outweigh the benefits. If there are many different types of boards, it is suggested not to use OSP finish unless there are specific requirements. Otherwise, the cost of saving on materials may cause issues in inventory management and result in overall higher costs.

Possible Degradation and Deterioration of Bonding Ability in Overdue PCBs.

After the production of PCBs, the adhesive ability between layers, or layer-to-layer bonding force, gradually degrades or even deteriorates over time. In other words, as time goes on, the bonding force between layers of the circuit board decreases.

When such a PCB goes through a reflow oven at high temperatures, the different materials composing the board may have different coefficients of thermal expansion. As a result of thermal expansion and contraction, it is highly possible for the circuit board to experience delamination, surface bubbles, and other issues. This will seriously affect the reliability and long-term trustworthiness of the PCB. When the board delaminates, it may break the via between layers, causing poor electrical characteristics. The most troublesome problem is the possibility of intermittent malfunction or CAF (conductive anodic filament) occurring without detection.

This article translate from 使用過保存期限的PCB會有何風險?烘烤就可以了嗎?

Related Articles:

Leave a Reply