Why is it necessary to partially increase the solder paste volume in SMT soldering?

To meet the demands of smaller and thinner electronic component designs, stencils are made as thin as possible to precisely control the tiny solder paste printed on the PCB.

However, this creates a challenge when smaller and larger electronic surface-mounted devices (SMDs) need to be mounted on the same board. The stencil’s thinness limits the amount of solder paste that can be deposited, and extending the stencil aperture over the pad size is still not yet enough to fill the necessary volume of solder. To provide sufficient solder paste volume for larger components, as well as for HTD components, EMS has implemented the PIH (Paste in Hole) process.

Here WorkingBear will provide some alternative solutions that EMS already did to deliver additional solder paste volume:

1. Solder Paste Manually with Semi-Automatic Dispensers

In some production lines, extra solder paste is manually added to the board’s land patterns using semi-automatic dispensers. This solution is suitable for situations where precise control of the solder volume is not required, such as for grounding tabs of connectors, smart card leads, and SIM card leads. However, this approach has several drawbacks, such as the need for additional operators on the SMT line, difficulty in controlling the solder paste volume and location, and the risk of human error, such as accidentally touching other components that are already in position.

2. Auto dispenser to add solder paste by machine

Auto solder paste dispenser can easily control the solder paste volume, location and less human error risk. However, disadvantage is that investment is needed to setup extra dispenser machine in the SMT production line.

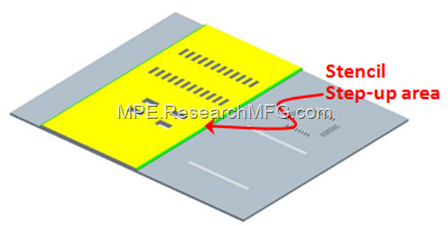

3. Apply the step-up or step-down stencil

The step-up or step-down stencil is made by using the laser solution to remove the certain area thickness in the stencil to partially increase or reduce the solder paste thickness volume for the designed components. However, the amount of thickness to step-up or step-down is limited. It can’t be increased or reduce too much from regular stencil thickness. For example, if uses a 0.10mm thickness of stencil then the certain area usually be increased to 0.127mm thickness only and can’t over 0.15mm. This is because most of component that needs to increase solder paste volume had small components locate on the adjacent area. The solder paste volume will be reduced gradually from certain thicker area of stencil to regular area. It is hard to control the gradually solder volume change. Too much of the solder volume will cause solder short for the small components and fine pitch IC.

Related article: What is Step-up & Step-down Stencil? Selective Solder Paste Volume Increasing Solution

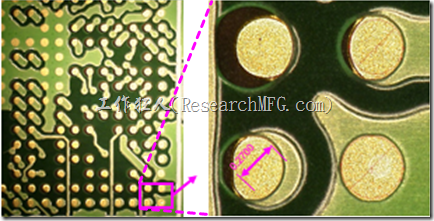

4. Apply the solder preforms

The solder preforms is a solid solder paste and form as standard shapes such as squares, rectangles, washers and discs. Typical sizes range from .010″ (.254mm) up to 2″ (50.8mm). Different sizes, as well as customized shape are available, but more expensive.The tape & Reel packing are also ready for the standard performs size to meet pick and place machine to improve the yield rate and save labor hours. It is usually placed on the printed solder paste during SMT process like a chip capacitor is placed using standard pick and place component libraries and equipment. It just like a solder paste needs go through the high temperature reflow oven then melt and joint the electric component with PCB pad together. It is recommended to use preforms with the solder paste together. Because preform is a solid shape and the paste will fix it on PCB without moving during transit in the SMT equipment path.

Related articles:

How to print solder paste on PC Board and screen printing notices?

Leave a Reply