This is a query from a user regarding SMT (Surface Mount Technology) processes, focusing on topics such as stencils, determining component placement sequence, and explanations of DFM (Design for Manufacturability) and DFX (Design for Excellence). We believe these questions and terms might also be of interest to those working in roles such as Project Management (PM), New Product Introduction (NPI), or procurement guys within electronic companies.

Often, when attending meetings with engineers, you may hear these technical terms without a clear understanding of what they actually mean. Not to worry, in this brief guide, we’ll attempt to explain these engineering terms in simpler language. Feel free to check back for updates if you have more related questions in the future.

Q1: What is a stencil? How is a stencil made, and at which stage of the SMT process is it used?

A1: The term “stencil” refers to a thin piece of steel, and the steel material can include options such as SUS304, SUS430, SUS301, as well as TA (Tension Annealing), SR (Stress Relaxation) and FG (Fine crystal Grain) treatments stencil. The dimensions of the stencil are typically standardized to match the specifications of solder paste printers. However, the thickness of the stencil varies based on specific requirements and can be chosen from options like 0.08mm, 0.10mm, 0.12mm, 0.15mm, 0.18mm, and others, depending on the application needs.

The purpose of a stencil is to assist in the solder paste application process. It is used during the SMT assembly process to precisely apply solder paste onto the PCB (Printed Circuit Board) before component placement. This ensures accurate and controlled deposition of solder paste onto specific areas of the board, allowing for the subsequent placement of surface mount components during assembly.

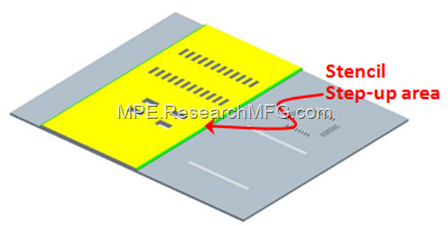

The purpose of using a “stencil” is to facilitate the printing of solder paste onto a PCB. Therefore, the stencil is engraved with numerous openings or apertures. During the solder paste printing process, the solder paste is applied on top of the stencil. The PCB is positioned beneath the stencil, and a squeegee (typically made of steel, as solder paste is a viscous substance similar to toothpaste) is used to spread the solder paste over the stencil. Under the pressure from the squeegee, the solder paste flows through the apertures in the stencil and adheres to the PCB. Once the stencil is lifted, the solder paste is visibly printed on the PCB. In simple terms, the stencil serves as a mask, akin to preparing a stencil when spray-painting. The solder paste is analogous to the paint, and the stencil, engraved with the desired pattern, helps achieve the intended design when the paint is sprayed on.

Given that the “stencil” is essential for printing solder paste onto the PCB, it becomes the first step in the SMT assembly process. After placing the PCB on the SMT production line, the next step involves utilizing the stencil for solder paste printing.

Solder paste is typically applied to facilitate the soldering of components onto the PCB. Consequently, whenever there is a change in the positions where components need to be soldered on the PCB, a new stencil must be created.

Further reading:

- How to Print Solder Paste on a Printed Circuit Board

- The Process of Manufacturing a Circuit Board in an Electronics Factory

Q2. I’ve read another article of yours. Are both smaller components (resistors, capacitors, etc.) and larger ones (connectors, etc.) now all processed through SMT and reflow? Is the insertion of THD components completed in the stage of a general pick-and-place machine? What about large components like CPUs and southbridge chipset; at which stage are they mounted?

A2. Nowadays, the majority of PCBA (Printed Circuit Board Assembly) processes use SMT to accomplish the soldering of all electronic components through reflow soldering. Even THD components can be treated as SMD (Surface Mount Device) components using the PIH (Paste-In-Hole) process for surface mounting. Typically, an SMT production line will have a combination of high-speed P&P (Pick and Place) machines, slow-speed (general-purpose) P&P machines, and sometimes an odd-form P&P machine. Small components are processed using high-speed P&P machines, while larger components (multi-pin) like BGAs (Ball Grid Arrays), CPUs, and connectors are often handled by slow-speed general-purpose P&P machines. Therefore, CPUs and southbridge chipset are usually placed using general-purpose P&P machines. Most SMT production lines configure multiple P&P machines based on actual needs, aiming for efficient production line balance.

For those interested in further understanding, you can refer to the article on “How EMS fabricate a PCB Assembly?”

It’s important to highlight that not every THD component can be considered equivalent to SMD components for reflow soldering. This is because they must adhere to temperature resistance standards and packaging specifications suitable for reflow temperature and P&P machines. For further details, you might find the article on the variances and consequences of transitioning SMD components to the PIH process informative.

It’s worth noting that not all THD components can be treated as SMD components for reflow soldering. This is because they need to meet temperature resistance requirements and packaging specifications compatible with SMT machines. For more information, you may want to refer to the article “What Process Impact of Substituting SMDs with Paste-In-Hole components?”

Q3. If a PCB requires double-sided (side 1, side 2, or A side, B side) SMT assembly, which side is assembled first? How is the decision made, and what are the determining factors?

A3. This question gets a bit intricate. Typically, in the initial design phase, product designers should decide the placement of components on the first and second sides based on DFM (Design For Manufacturing) specifications. However, plans might not always unfold smoothly. The factory might not offer DFM recommendations, or design engineers might intentionally overlook DFM requirements due to space and other limitations.

Now, let’s think about the scenario where components are assembled on the first side of the board, and then the second side components are added, causing the initially placed components on the first side to flip to the bottom. When the second side components undergo assembly, the entire board undergoes the high-temperature reflow soldering process once again. If there are heavier components on the bottom (first side), there’s a risk of them falling due to gravity, and there’s a chance of the solder reflowing.

As a general practice, the side with heavier components is usually assembled on the second side. Moreover, when dealing with BGA or LGA components, concerns might arise regarding the potential impact of the second reflow on component displacement and solder reflow issues. Hence, it’s often recommended to assemble these components on the second side to go through the reflow process only once. However, opinions may vary, and it’s advisable to consider the actual circumstances. For fine-pitch components, if precision alignment is crucial, it’s generally better to assemble them on the first side, as the board tends to warp after the first reflow, affecting solder paste alignment and control.

Of course, these are general principles, and exceptions are common. The choice often depends on selecting a step with minimal impact on the process and optimizing quality.

Related articles:

- How to Avoid Dropping Heavier Components on the First Side During Secondary Reflow

- Introduction to PCBA Double-Sided Reflow Soldering Process (SMT) and Considerations for Component Placement

Q4. How to avoid the risk of components falling during reflow when both sides have heavy components?

A4. If the first side has heavier components, you can overcome the issue of components falling during the second reflow by using the following methods:

-

SMT red glue: Dispensing red glue under the components. This involves dispensing a special type of adhesive (often red in color) beneath components to provide additional support during the reflow process.

-

Reflow Carrier: Using reflow carriers or fixtures from below to support components that might fall. These fixtures can be reusable, but they require manual handling for installation, removal, and transportation, which can be time-consuming and labor-intensive.

Related article:

- Reflow Carrier for Composite Stone Tray

- How to Evaluate the Risk and Probability of Electronic Components Not Falling Off during SMT Second Reflow

- Why Don’t devices Fall Off on First Side during SMT Second Reflow? Does the solder MP increase during the second reflow?

Q5. Sometimes, engineers discuss adding “red glue” to components due to the design of the board. However, red glue is said to be for wave soldering, which our board doesn’t have. Why is that?

A5. In the past, during the popularity of wave soldering, red glue was indeed applied on one side of the PCB (usually the second side). SMD components were then placed on top, and after passing through a reflow oven, the red glue solidified to hold the components in place. Finally, the board would go through wave soldering. As the board slid over the molten tin in the wave soldering bath, the components were immersed in the tin. The red glue prevented the components from falling into the tin bath.

Related article: What is SMT Red Glue (Dispensing) process? What are the limitations while use red glue process?

Since red glue can stick components in place, preventing them from falling into the wave soldering pot, can it be used to adhere heavier components on the first side in double-sided SMT assembly during reflow to prevent them from falling? The answer is undoubtedly yes. So, when engineers discuss using red glue, they’re talking about securing components that might otherwise fall during the second pass through the reflow oven. This additional processes increase production costs and the likelihood of errors, so it’s always a topic of discussion among engineers.

Q6. I often hear engineers and process engineers in factories talking about DFX and DFM, but I’m not quite sure about the meanings of these terms. Could you help clarify?

A6. DFM stands for Design For Manufacturability, and DFX, where X can be various factors, includes DFT (Design For Testability), DFA (Design For Assembly), and, of course, DFM. In the context of discussions in manufacturing factories, DFX and DFM often refer to the same thing—how the design can be improved to better align with the quality and efficiency of factory production.

For more information on DFX and DFM, you can refer to this article: What is DFX? What is DFM? What Are Their Full Forms?

Related Posts:

Leave a Reply