Today, most of electronic components are developed into smaller size. The small chips are downsized from 1206 to 0805, 0603, 0402, 0201, even to 01005. The size of chip is smaller; the required solder volume is less.

Moreover, the required stencil thickness becomes thinner from 0.18mm to 0.10mm or 0.08mm. Some components, however, cannot be downsized unlimitedly, such as external connectors. For example, a line socket of telephone, a network line socket, a smart card reader, and other devices require a certain amount volume of solder to ensure the soldering strength and quality. In addition, some traditional insertion parts (THD, Through Hole Devices) with paste-in-hole process require extra solder volume as well.

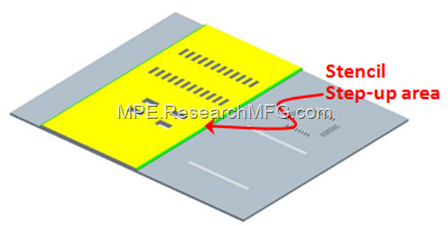

Then, how can we adopt a thinner stencil with solder volume partially increasing? One solution is “Step-up & Step-down stencil” for the increase of partial solder volume. However, this kind of stencil can increase only limited solder volume. In addition to the problem of limitations, there is also an issue of insufficient solder.

Therefore, another solution called “Solder Preforms” hit the market. On solder preforms, each kind of solder can be developed in accordance with real requirement. Since the solder preforms is a tin-based bar compressed by force, it can cover the insufficient solder issue due to the limitation of printing stencil. Moreover, the solder preforms is packed based on the type of tape and reel in general. Therefore, they can be pasted/printed through SMT machine to save manpower and prevent operators’ mistakes.

The advantages of solder preforms are listed as follows:

1. The solder paste volume can be increased in paste-in-hole process so that DIP can adopt fuller solder volume to avoid insufficient solder issue and voids.

Solder Preforms adopted in the Pin-In-Paste process.

|

|

2. It can both reduce the non-wetting rate caused by the co-planarity of part pins and enhance the solderability. The preforms can be put on pads for solder volume increase. Please note that the preforms should be put on the area contacting the pads in order to increase the solder volume after tin melting.

Besides, the solder preforms can be adopted for other purposes. For example, a solder preform can be put between two metal parts for contacting buffer. They can also be adopted for safety switches. They can lead short-circuit to trip out the power supply for fusion temperature.

The disadvantages of solder preforms:

-

The solder-preforms is an extra cost. You may choice another cheap solution to increase the solder volume before select this solder-preform solution. As my experience it cost will be 10~100 times as compare with same size of 0402 resister.

-

The solder-preforms must put on the solder paste just like the small chip components to prevent it from moving or dropping during SMT conveyor transfer.

Most of the solder-preforms supplier provide tape-on-reel packing. The solder-preforms can be pick and place on the PCB just like regular SMT process.

Related article:

Leave a Reply