What is the difference between PCB and PCBA? This is actually something that should be easily understood, but since someone asked, Workingbear will try explain it briefly here. If any readers notice any errors, please feel free to correct me.

Most people are probably familiar with the term “PCB,” and if you’ve read some stock-related financial articles, you’ve likely heard of it. However, if you’re not in the electronics industry, you might be less familiar with the term “PCBA,” and you might even confuse it with PCB. Although PCB and PCBA differ by only one letter, they have a significant difference in the electronics manufacturing industry.

What is a PCB (Printed Circuit Board)?

The full name of PCB is “Printed Circuit Board,” which is sometimes called “PWB (Printed Wire Board).” PWB is commonly used in some countries, but in Taiwan and China, it is mostly referred to as PCB.

Printed Circuit Board (PCB) manufacturing is essentially a technology that mimics the printing process of books on paper. A piece of hard board is used, and the copper foil circuit is printed on it through a chemical etching method after light projection onto a negative film. Although the manufacturing process of PCBs has become more sophisticated and complex with technological advancements, the printing process and operation still exist.

If you are interested in the PCB manufacturing process, you can refer to this article: [Video] Introduction to PCB Production Process.

The reason why today’s electronic products have so many functions is essentially due to the combination of electronic circuits and electronic components. These circuits must have a carrier, and PCB is this carrier with electronic circuits on it, and it must also carry electronic components without losing functionality. It is responsible for communicating the channels between electronic components.

Therefore, if the earth is the carrier, the electronic circuit is the road that connects towns and cities, and PCB is the land already covered with roads, while electronic components are cities and towns.

Have you noticed the role of PCB here? Yes, it is like a country with completed land planning, waiting for the chief of state to install different functional cities and towns (components) in specific locations. When all the electronic components are assembled onto the PCB, it is called PCBA. So now you should have a rough idea of the difference between PCB and PCBA.

We usually call the PCB with printed electronic circuits but not yet assembled with components as “bare board” to distinguish it from PCBA. Although the two terms only differ by one English letter, they are entirely different things.

PCB is one of the essential electronic components in the electronics industry. It is the carrier of electronic components and the transmission channel of electrical connections between electronic components. Of course, FPC (Flexible Printed Circuit) can also serve as a carrier and signal transmission function like PCB, but they have their own requirements and applications. In most electronic product designs, “hard board PCB” is still the primary application.

The uniqueness of PCB can be summarized as follows, which has gained widespread use in the industry:

-

High wiring density, small size, and light weight, which is beneficial for miniaturization of electronic products. Recently, PCB density has gradually approached early integrated circuit technology, and some processes have tended to use semiconductor equipment.

-

High reproducibility, which can be mass-produced to achieve repeatability and consistency, reducing the problem of assembly errors using cables. Modular design can enhance equipment maintenance, debugging, and inspection time.

-

It can be produced automatically. PCB and PCBA can now be almost fully automated, reducing labor costs and operating errors, and improving labor productivity, which is beneficial to lower product prices and popularize the market.

-

Standardization can be achieved in design, and it can be designed into modules. When different functions are needed, replacing the entire PCBA board is sufficient.

What is PCBA?

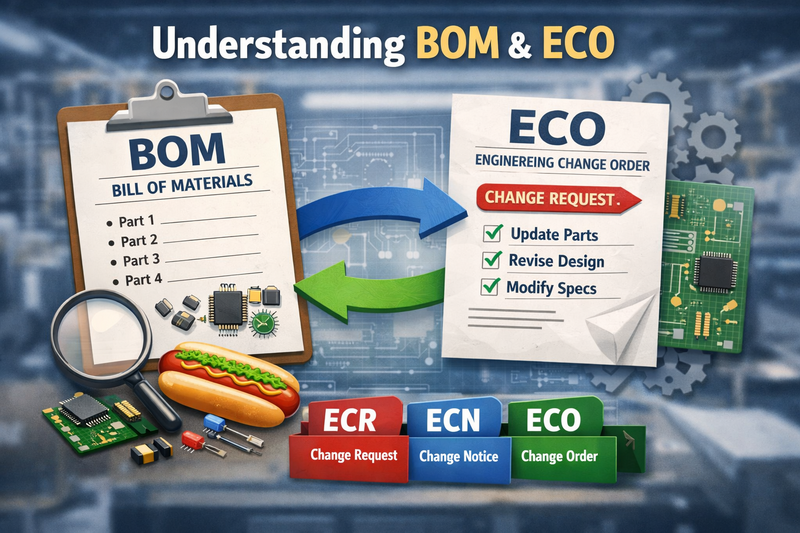

The difference between PCB and PCBA is that “PCBA = PCB + Assembly”, meaning that a board without assembled electronic components is called a PCB, while a board that has already been assembled with electronic components is called a PCBA.

To make an analogy, think of PCB as the earth with a road on it, but without any towns yet, while PCBA is the earth with the road and the towns already in place.

PCBA stands for “Printed Circuit Board Assembly”, and some people abbreviate it as PCA or PWA (Printed Wire Assembly). However, people working in electronics assembly factories rarely call it PCBA because a set of electronic product may have more than one PCBA. If there is only one PCBA inside the product, we would simply call it the “main board”, and if there are more than two PCBAs, we would use the functions to differentiate them, such as main board, IO board, and charging board.

How are electronic components placed on the PCB to form a PCBA?

Currently, the most popular PCB Assembly method is SMT (Surface Mount Technology). This method involves first printing solder paste on the empty board and then mounting the electronic components on the PCB. The PCB then goes through a high-temperature reflow oven, which attaches the components to the board through the solder paste.

Currently, the most popular PCB Assembly method is SMT (Surface Mount Technology). This method involves first printing solder paste on the empty board and then mounting the electronic components on the PCB. The PCB then goes through a high-temperature reflow oven, which attaches the components to the board through the solder paste.

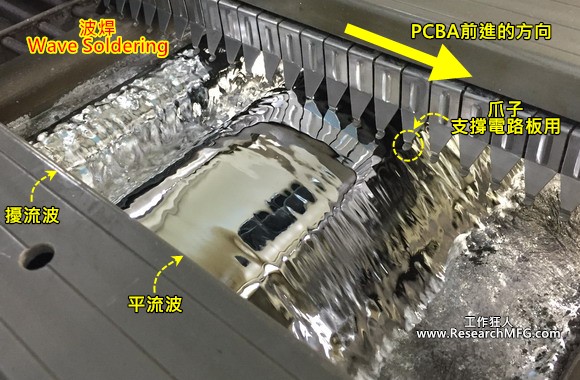

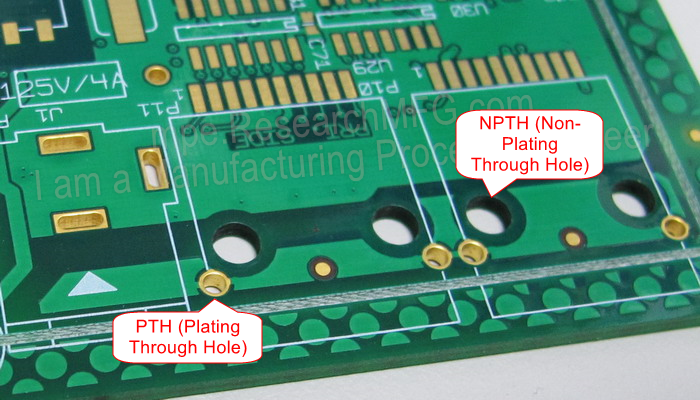

Some PCB Assemblies use “wave soldering” technology. Generally, there are some electronic components on the assembled board that are relatively heavy or need to withstand external forces such as plugging and unplugging. These components may not be able to be made as SMD (Surface Mount Device) type of components due to technical limitations, or the price of making them as SMD components may not meet market expectations. Instead, they are designed as through-hole devices (THD) and then soldered to the PCB through a wave soldering machine.

In addition, there are PCB Assembly designs that use a combination of SMT and wave soldering technologies to complete component soldering on the PCB.

After the above introduction, you should now be able to clearly distinguish what is PCB and PCBA. PCBA can basically be considered a finished product because some factories produce and ship PCBA as a standalone product, such as computer motherboards. PCB, on the other hand, can only be considered as a component. While PCB is an important component of a finished PCBA, it cannot represent PCBA because ICs, resistors, capacitors, inductors, connectors, and other parts need to be soldered onto the PCB to become a finished product. Therefore, PCB can only be considered as a main component.

Related Articles:

Leave a Reply