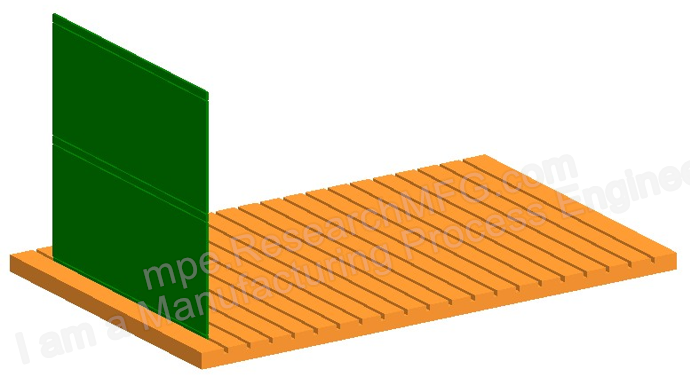

There are many ways to de-panel or remove the edge rails of a PCB, but the simplest and cheapest method is manual V-cut breaking. However, this method can easily lead to uncontrolled quality issues. Before using manual breaking, it’s important to confirm that the board really cannot be processed with a V-cut scoring machine, or that the components on the PCBA are strong enough to handle bending stress without damage.