Recently WorkingBear got complaint from R&D and ask increase the solder paste volume on the MLCC (Multi-Layer Ceramic Capacitor) component pads to improve the capacitor broken issue. R&D said he had verified that the capacitor’s footprint in the board design is correct and followed manufacturer’s design guidelines. However, looks like there is not enough solder paste to form proper heel fillet on the terminal of capacitor. This insufficient solder paste volume make the solder cracking?

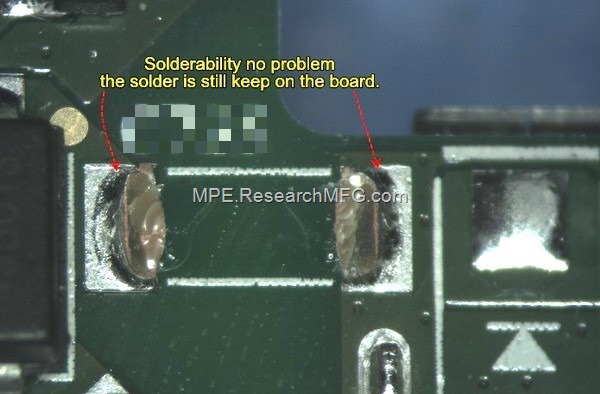

Recently one of my top manager ask to mount the shielding-can or call shielding-cover directly on the Printed Circuit Board to instead of mount the shielding-clip or call shielding-frame on the board first then cover the shieling-can. He said this “new process” is more cheap and can reach better RF (Radiation Frequency) performance. Also most of current popular cell phone board apply this solution.

Recently one of my top manager ask to mount the shielding-can or call shielding-cover directly on the Printed Circuit Board to instead of mount the shielding-clip or call shielding-frame on the board first then cover the shieling-can. He said this “new process” is more cheap and can reach better RF (Radiation Frequency) performance. Also most of current popular cell phone board apply this solution.

One day, my manager asked me a question: “Will changing the components from SMDs (Surface Mount Devices) to THDs (Through Hole Devices) and using the PIH (Paste-In-Hole) process affect the process and design?”

One day, my manager asked me a question: “Will changing the components from SMDs (Surface Mount Devices) to THDs (Through Hole Devices) and using the PIH (Paste-In-Hole) process affect the process and design?”