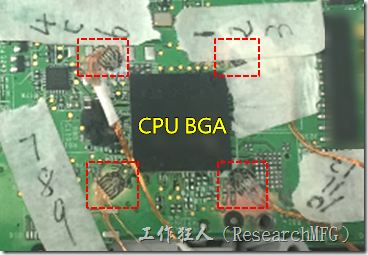

The earlier sections of the article that Workingbear spent a lot of time discussing how to strengthen the bonding force of PCBAs and increase the stress resistance of electronic products. Now, we can finally talk about the biggest culprit causing BGA solder joint cracks: stress.

To completely solve the problem of BGA solder joint cracks, we must understand where stress comes from and treat it accordingly to avoid or reduce its impact. Without addressing stress issues, all other efforts will only be half as effective, just like managing floodwaters – clearing them is always more effective than building barriers.