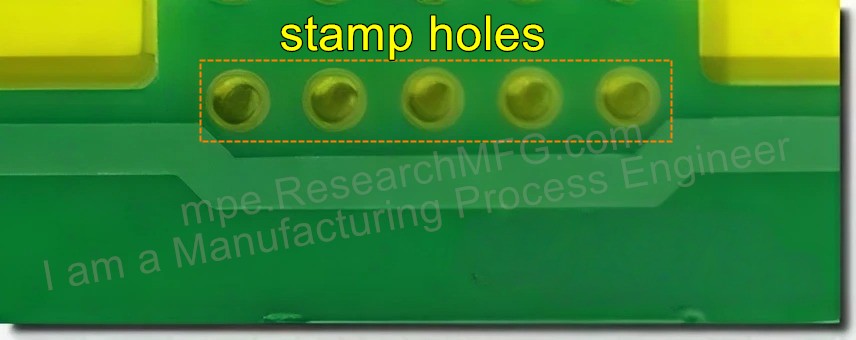

When making printed circuit boards (PCBs), individual boards are first combined into a big panel board. After components mounting or soldering, they are separated into individual boards using de-paneling tools.

This article summarizes the three most common PCB de-paneling methods used in the industry today:

- PCB De-paneling — Router Cutting Machine

- PCB De-paneling — V-Cut Scoring Machine

- PCB De-paneling — Manual Breaking