There are several methods to cut and separate pre-panelized PCBs into individual boards, and one commonly adopted approach for thin and finely dimensioned mobile phone PCBs is using a Router Cutting Machine. It offers numerous advantages over V-Cut scoring machines, with the primary benefit being a higher quality of panel separation, surpassing the benefits of manual operation.

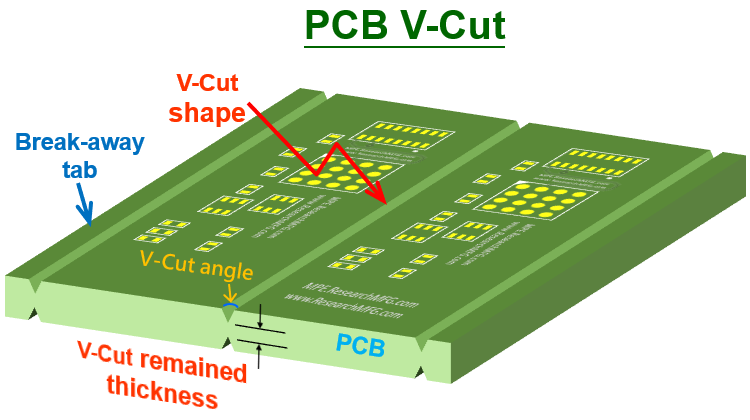

If you’re not yet familiar with why printed circuit boards (PCBs) are panelized before assembly and then separated, please refer to the article titled “Why is Panelization and Break-away Tab Necessary in PCB Manufacturing, then De-paneling after PCBA is Completed?”