There are several methods to cut and separate pre-panelized PCBs into individual boards, and one commonly adopted approach for thin and finely dimensioned mobile phone PCBs is using a Router Cutting Machine. It offers numerous advantages over V-Cut scoring machines, with the primary benefit being a higher quality of panel separation, surpassing the benefits of manual operation.

If you’re not yet familiar with why printed circuit boards (PCBs) are panelized before assembly and then separated, please refer to the article titled “Why is Panelization and Break-away Tab Necessary in PCB Manufacturing, then De-paneling after PCBA is Completed?”

The video above demonstrates how the Router Cutting Machine works for panel separation.

Here, there is a relatively long video that explains how a Router (de-paneling machine) works for board separation and highlights important considerations.

Router Cutting, in essence, employs XYZ-axis milling cutters to mill the interconnections between PCBs. The advantage of using a router lies in its ability to reduce bending stress, but the process tends to generate dust, often necessitating the use of exhaust systems. Additionally, during routing, there’s rotational inertia to consider, so it’s advisable to have alignment holes in the individual boards for post-cutting securing. Otherwise, the PCBs might be ejected. Alternatively, the outer shape of the board can be used for alignment during the process.

Advantages of Router Cutting (De-paneling):

-

Non-linear Cutting: Router machines can perform non-linear cuts, unlike V-Cut, which can only make straight cuts.

-

Assured Complete Cutting: Router machines ensure a thorough separation of the PCB, eliminating issues where V-Cut might fail to cut through completely.

-

Reduced Component Stress: The routing process is less likely to cause problems like component or solder joint cracking due to bending stress, as it involves lower levels of stress.

-

Minimized Component Damage: Router cutting is less likely to damage components on the printed circuit board. In V-Cut cutting, the PCB typically drops directly onto the work surface, increasing the risk of damaging board components.

-

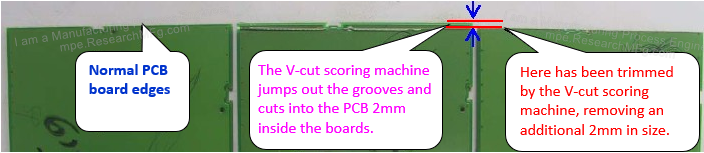

Alignment Precision: Aligning the V-Cut grooves with circular blades can be challenging and often relies on manual alignment, which is prone to error. Improper alignment can cause the blade to jump out of the groove and cut in the wrong position, potentially damaging the circuit board.

However, Router de-paneling machines also come with some disadvantages:

-

The equipment cost for Router machines is higher compared to V-Cut scoring machines.

-

Customized supporting fixtures are required for each type of panelized PCB to prevent PCBA from falling into the cutting equipment during de-paneling.

-

Alignment holes must be incorporated into single boards to facilitate support during the cutting into individual panels and prevent PCBA from being thrown during the de-paneling process.

-

It is advisable for the cutting equipment to have exhaust systems. This is because Router de-paneling generates PCB dust and debris, which can be harmful to human health and potentially affect subsequent assembly processes for the final product.

(↓ The image below illustrates the damage caused by incorrect V-Cut cutting.)

Related Articles:

Leave a Reply