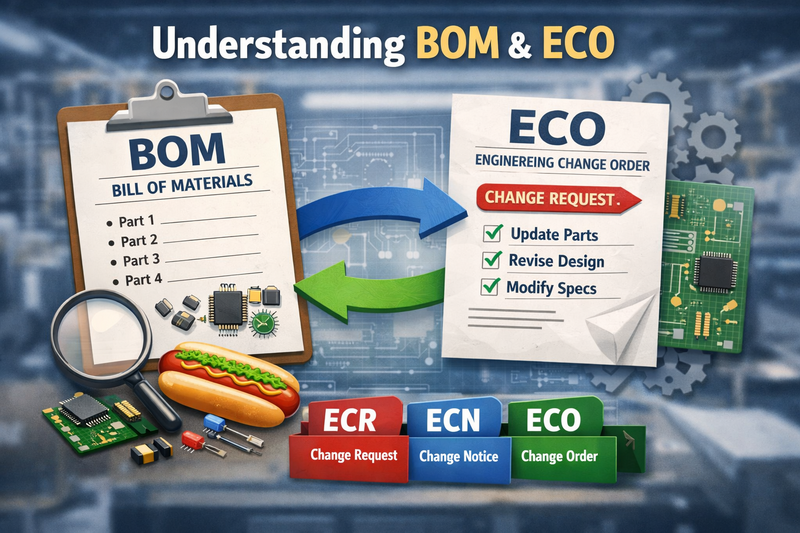

For many people who are new to the electronics manufacturing and assembly industry, BOM and ECO are two very important terms—but also two of the most confusing ones. In this article, I’ll try to explain these concepts in a simple and easy-to-understand way.

When Workingbear first entered the electronics manufacturing industry, hearing the term “BOM” for the first time was confusing. Workingbear honestly thought it had something to do with “bombing” (don’t laugh 😄). “ECO” was even more confusing—though it was obviously not the “ECO-Navi” energy-saving mode often seen in air conditioner ads or car commercials.