Today, most of electronic components are developed into smaller size. The small chips are downsized from 1206 to 0805, 0603, 0402, 0201, even to 01005. The size of chip is smaller; the required solder volume is less.

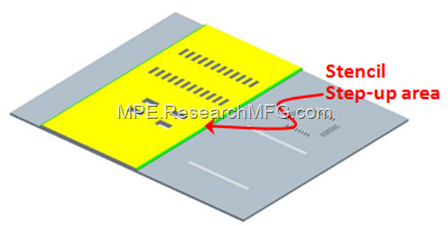

Moreover, the required stencil thickness becomes thinner from 0.18mm to 0.10mm or 0.08mm. Some components, however, cannot be downsized unlimitedly, such as external connectors. For example, a line socket of telephone, a network line socket, a smart card reader, and other devices require a certain amount volume of solder to ensure the soldering strength and quality. In addition, some traditional insertion parts (THD, Through Hole Devices) with paste-in-hole process require extra solder volume as well.

The trend in the electronics industry is toward smaller and smaller SMD components, with sizes such as 0402, 0201, and even 01005 becoming common (Note 1). Additionally, the pitch between pins on ICs has decreased to a fine pitch of 0.5mm, and even 0.3mm, posing a challenge for the SMT process.

The trend in the electronics industry is toward smaller and smaller SMD components, with sizes such as 0402, 0201, and even 01005 becoming common (Note 1). Additionally, the pitch between pins on ICs has decreased to a fine pitch of 0.5mm, and even 0.3mm, posing a challenge for the SMT process.