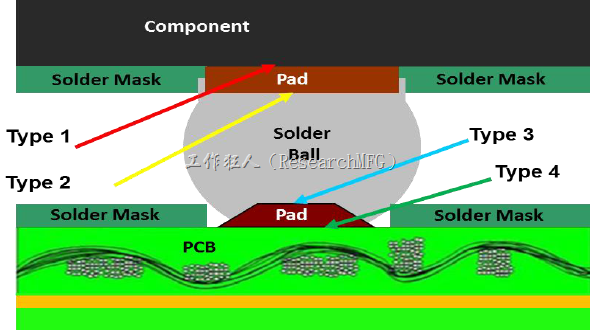

What is the actual root cause of BGA solder ball cracking? Stress is higher than its bonding-forces.

The root cause of BGA solder ball cracked is stress higher than bonding-forces.

Stress is higher than bonding-force is the certain result of BGA solder ball cracked.

BGA solder ball cracked is the certain result of stress higher than bonding-forces.

Working-Bear spent lots of time to prepare this serial article. Don’t just do copy and paste to steal my babies. There will be total 13+1 articles in this blog mentioned the BGA (Ball Grid Array) component drop and solder balls cracked issue. The most concepts that you may know already but here I summary them together systematically and let you read them easily.

“Stress > Bonding-force”

is the root cause of electronic components drop from the PCB and solder crack.

This is not the first time that Working-Bear be challenged the soldering problem from R&D once the NPI run found any components has solder crack. Our RD always came to me and challenged why EMS can’t make thing right to guarantee the solderability. Some RD even ask me need to increase the solder paste volume to improve the soldering strength. It is really enough!

read more…》