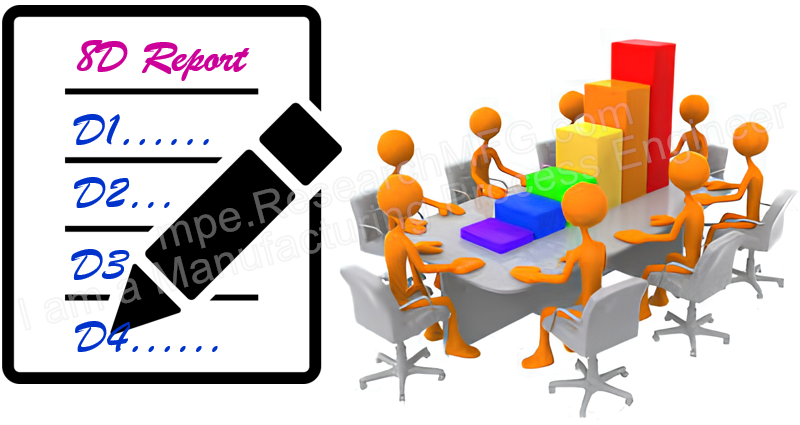

The “8D report” is a tool commonly used in the electronics assembly industry for “problem analysis and solving.” Due to its systematic and clear steps, the “8D report” is often utilized in responding to customer complaint cases.

The term “8D” refers to the “8 Disciplines process.” The person filling out the report generally follows predefined steps in sequence. This helps most quality control personnel systematically identify the causes of problems step by step. It also allows you to explain to the customer how the problem was discovered or occurred, how you analyzed the problem, found the root cause, verified if the problem was genuinely resolved, and implemented preventive measures to prevent the problem from recurring.

read more…》