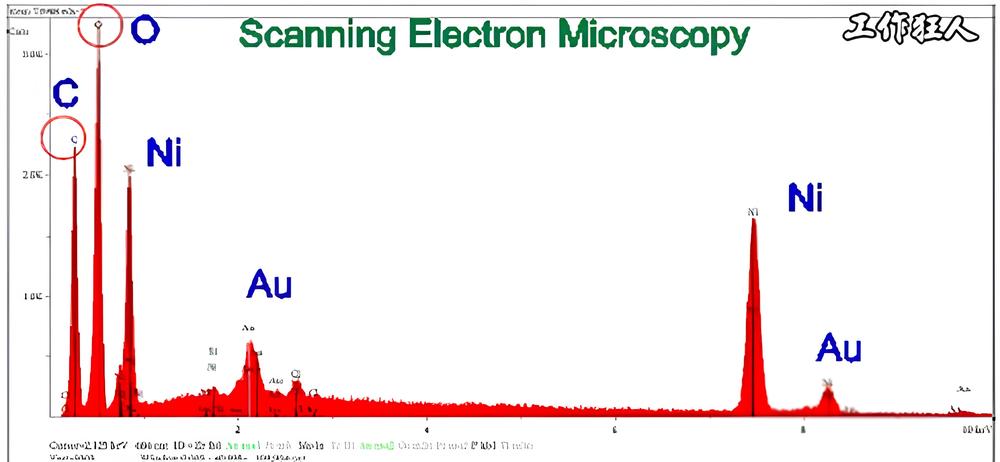

Energy-Dispersive X-ray Spectroscopy (EDS or EDX) is a common, non-destructive technique used in the industry to quickly identify the elemental composition of a sample’s surface. In electronics manufacturing and material analysis, knowing what elements are present is critical for quality control and surface-level failure analysis.

Although EDX is considered non-destructive, there are some limitations. Most EDX equipment has size restrictions, so it’s a good idea to check with the lab beforehand to make sure your sample fits. Also, in many cases, the sample needs to be cross-sectioned before analysis. That’s because EDX can only detect elements within about 5 microns (µm) from the surface, so it’s best suited for surface-level analysis.