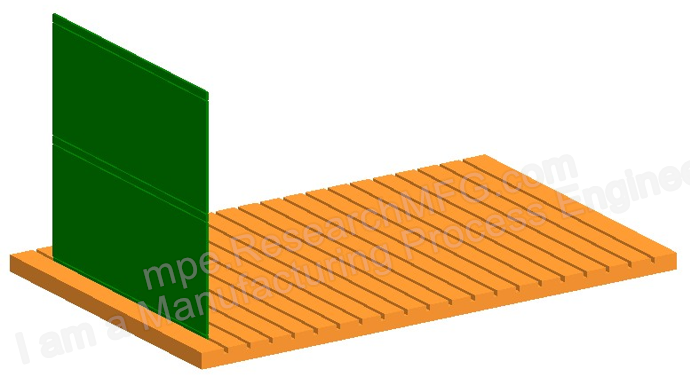

When making printed circuit boards (PCBs), individual boards are first combined into a big panel board. After components mounting or soldering, they are separated into individual boards using de-paneling tools.

This article summarizes the three most common PCB de-paneling methods used in the industry today:

- PCB De-paneling — Router Cutting Machine

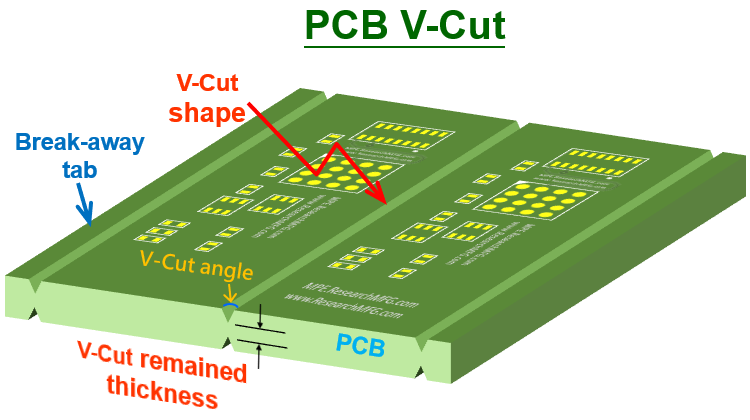

- PCB De-paneling — V-Cut Scoring Machine

- PCB De-paneling — Manual Breaking

Of course, there are two other PCB depaneling methods, but they’re not covered in this article:

-

Laser depaneling. This method isn’t widely used yet.

-

Punch-type depaneling. This approach is rarely used today. Some PCB factories may still use it, but it’s not included in this discussion.

Best Quality: Router • Best Value: V-Cut • Lowest Cost: Manual

From a quality standpoint, the router cutting machine gives the best and most consistent results, but it’s also the most expensive and time-consuming.

Manual breaking is the cheapest method but the hardest to control, with a high chance of damaging components or solder joints.

| Method | Quality | Cost |

|---|---|---|

| Router | High | High |

| V-Cut Machine | Medium | Medium |

| Manual Break | Low | Low |

Overall, V-Cut machines are usually preferred for standard PCBA de-paneling because it provides the best value. However, since V-Cut can only make straight cuts, boards that require curved or irregular cuts must use a router or manual breaking insteads, and very thin boards may not be suitable for V-cut grooves.

For boards that cannot use a V-cut machine, you can then decide whether to use a router depanel machine or a manual break-off method.

Here are some general guidelines for choosing the right method:

When to Use a Router De-panel Machine

-

Smartphone boards — These usually have many small components and thin boards (0.8–1.0 mm). Workingbear strongly recommends using a router if the PCB is thinner than 1.0 mm. This helps prevent cracks in capacitors or BGA solder joints caused by stress during bending or de-paneling.

-

Stress-sensitive components — Use a router when parts or soldering joints on the PCB cannot handle flex stress.

-

High-reliability products — For boards where long-term performance and durability are critical.

-

High-density boards — Because solder joints are smaller and weaker.

-

Thin boards — As mentioned, PCBs under 1.0 mm are better processed by routers.

-

Boards without V-Cut lines — When V-Cut can’t be applied due to layout limitations.

When to Use Manual Breaking (V-Cut Folding)

-

When a V-Cut machine cannot be used, and the reliability requirement is not too strict. For example, simple boards with parts crossing the V-Cut line.

-

When all components can handle some bending — such as through-hole devices (THDs), which have stronger solder joints compared to SMD parts. However, careful handling and consistent technique are still required. Thin components or MLCCs are especially sensitive to board bending and may crack easily (crack or micro-crack).

-

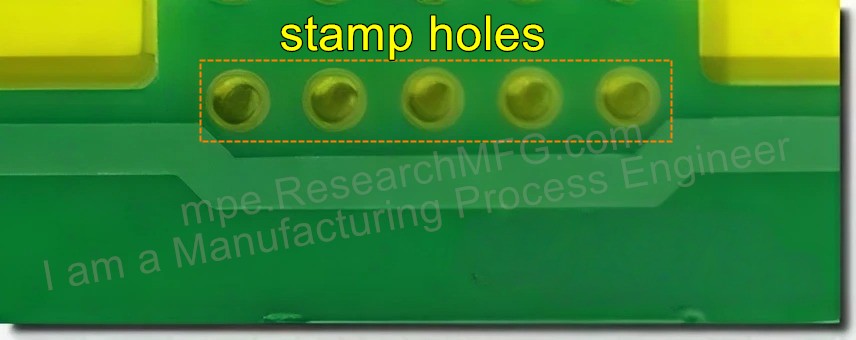

For stamp hole (perforated) panels, which are often used for prototypes, small batches, or DIY-style production. These are usually broken apart with diagonal cutters, but manual breaking is hard to control and often requires sanding or filing afterward.

If possible, treat stamp holes as tabs/ribs and use a router or laser cutter to separate them for better quality and consistency.

Related Posts:

Leave a Reply