BOMs, AML/AVL, and MPNs are essentially the “recipe” behind electronics manufacturing. All of these terms are closely related to a product’s material list. Understanding what they mean is not difficult—the real challenge is knowing how to apply them effectively to achieve proper material control within a company.

BOM (Bill of Materials)

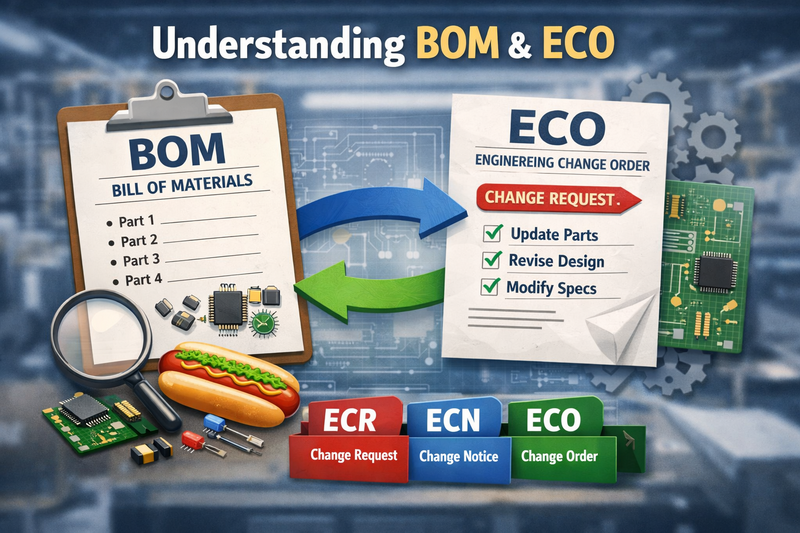

Workingbear has previously written about the relationship between the BOM and ECO, with detailed explanations of what a BOM is. Even so, some readers still have questions about how to use a BOM to manage materials from multiple suppliers. Below is a real-world question that came up:

Sorry to bother you, but may I ask a question about BOM management?

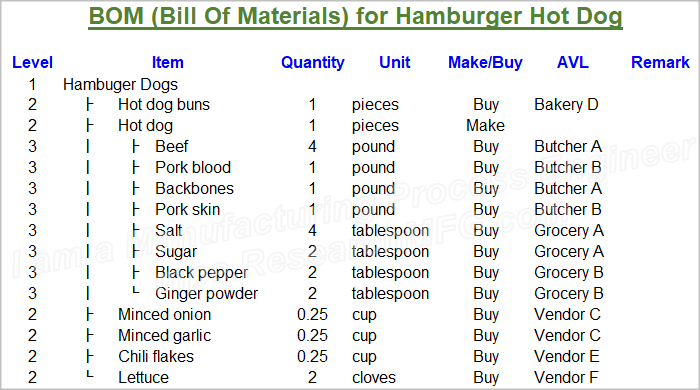

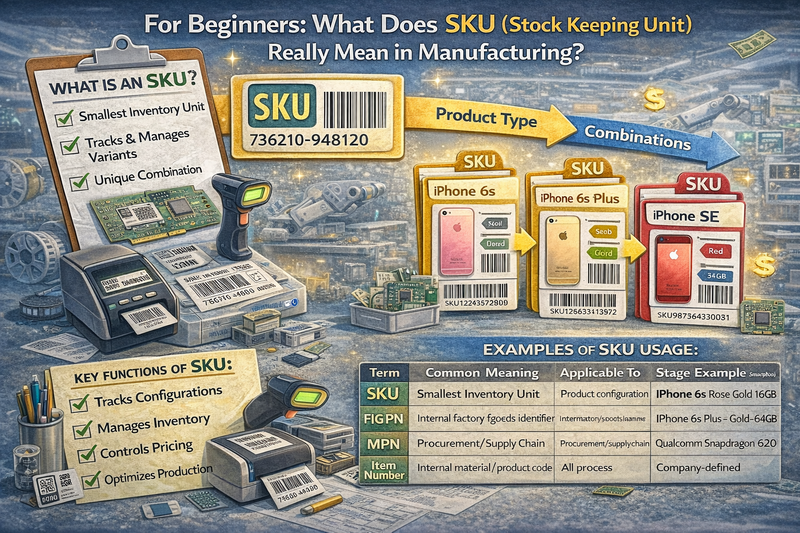

In our BOM, for passive components (such as MLCCs and chip resistors), we usually use one internal part number linked to three different brands (AVL), each with its own MPN. For example, part number 10PF01 may represent a 10 pF capacitor from Murata, TDK, or Yageo.

Recently, our QA team suggested separating different brands into different internal part numbers to improve yield control—for example, 10PF01 for Murata, 10PF02 for TDK, and 10PF03 for Yageo.

R&D originally set up the BOM from a design perspective, while QA is looking at it from a production perspective. Both make sense, and now we’re not sure which approach is better.

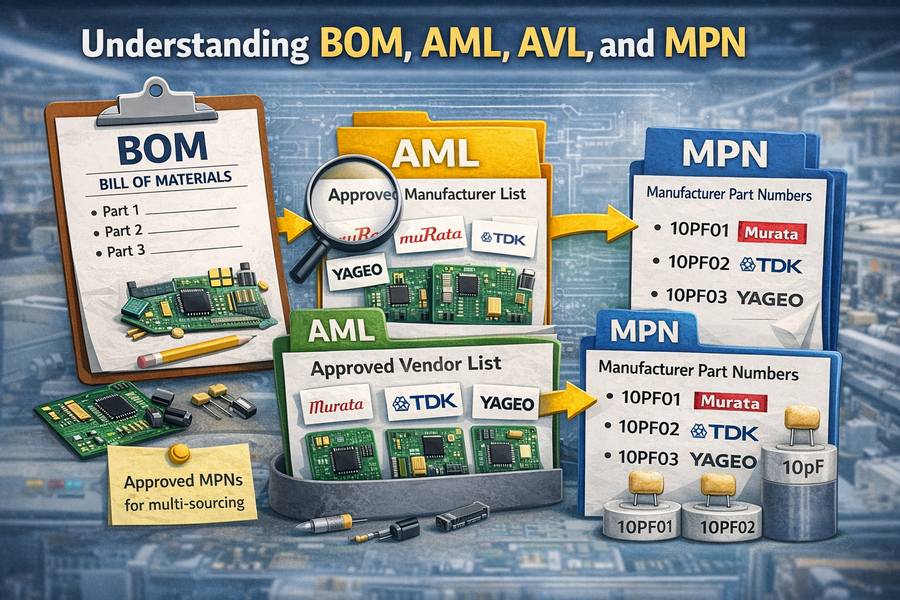

This question actually involves several related concepts. In previous articles, Workingbear explained that a BOM not only includes item names, internal part numbers, descriptions, quantities, and units, but should also include supplier information (AML or AVL), manufacturer part numbers (MPN), and material specifications.

This article focuses on three key manufacturing-related terms:

-

AML: Approved Manufacturer List

-

AVL: Approved Vendor List

-

MPN: Manufacturer Part Number

What Are AML and AVL?

AML (Approved Manufacturer List) and AVL (Approved Vendor List) generally refer to the same idea, just described using different terms. Both represent a list of approved manufacturers or suppliers. Some companies even include distributors in these lists. Other companies strictly define AML as original manufacturers and AVL as authorized distributors. Personally, Workingbear feels the practical benefit of strictly separating manufacturers and distributors is often limited.

Whether it is AML or AVL, suppliers typically must pass a formal approval process—such as quality audits, process audits, financial reviews, and procurement evaluations—before being allowed to deliver materials. Purchasing is then restricted to these approved suppliers to ensure material quality.

Most mid- to large-sized companies have a formal supplier qualification system. Not just any supplier can ship parts—otherwise, what happens if poor-quality materials are delivered or production losses occur? Some companies use evaluation checklists such as TQRDCE, while many today follow more comprehensive supplier quality systems aligned with standards like ISO/TS or IATF 16949.

In short, AML/AVL exists to define which suppliers are qualified partners.

What Is an MPN?

An MPN (Manufacturer Part Number) identifies a specific part produced by an approved supplier. Even if a supplier is approved, you still need to specify exactly which part you want. You cannot simply say, “I need materials.” You must provide the exact part number so the supplier knows what to deliver. That part number is the MPN.

Another purpose of managing MPNs is capability control. Not every approved supplier can manufacture every type of part you need. For example, not all PCB manufacturers can produce IC substrates. Even if you place an order, they may not be capable of making it. Just like you wouldn’t expect to buy vegetables at a pork butcher’s stall, different suppliers specialize in different products.

Even suppliers producing similar products may have different capabilities or quality levels. Some may offer additional processing services, while others cannot. That’s why it’s important to match the right supplier with the right part. Unfortunately, many companies struggle with this in practice.

In short, MPNs define which approved suppliers are capable of producing a specific part.

Back to the Original Question

From the description above, it’s clear the company already understands AML, AVL, and MPN concepts. AML and AVL define qualified suppliers, while MPNs identify the specific parts those suppliers provide. A single internal part number can legitimately be linked to multiple MPNs—such as three different suppliers offering equivalent 10 pF capacitors.

This is a typical second-source strategy. Its main goals are to prevent production stoppages due to supplier shortages and to give purchasing leverage for price comparison and negotiation. However, this only works if all MPNs truly meet the same functional specifications—and ideally share the same package size and soldering dimensions. Otherwise, design or production issues are likely to occur. If you split one 10 pF capacitor into three separate internal part numbers, you lose the real purpose and value of second sourcing.

That leads to a key question: Are these three MPNs truly equivalent?

If not, they should never have been grouped under the same internal part number. And if a certain supplier consistently causes quality issues in production, that MPN—or even the supplier itself—should not have been approved in the first place.

Traceability in Production

Another common production challenge is identifying which supplier’s part is actually used on a specific PCBA, especially when incoming quality issues occur. This is usually the core concern of QA teams.

The solution typically lies in SMT material management systems combined with scanning and tracking tools. Most well-established EMS companies require all SMD materials to carry barcodes on packaging and reels. Materials are scanned before loading, which verifies correctness and records which supplier’s parts are used on each batch of boards.

In the 2020s, many EMS providers have gone even further by implementing MES (Manufacturing Execution Systems) integrated with barcodes, QR codes, RFID, and even AI-based visual recognition. This enables much more accurate, real-time tracking of which MPNs are actually used on each PCBA, greatly improving quality traceability.

Practical Recommendation

From Workingbear’s perspective, if a company has already implemented an integrated PLM + ERP system, the preferred approach is to use one internal part number with multiple approved MPNs, supported by MES for actual usage tracking—rather than splitting internal part numbers by supplier. This approach preserves the benefits of second sourcing while maintaining control and traceability in production.

Related Posts:

Leave a Reply