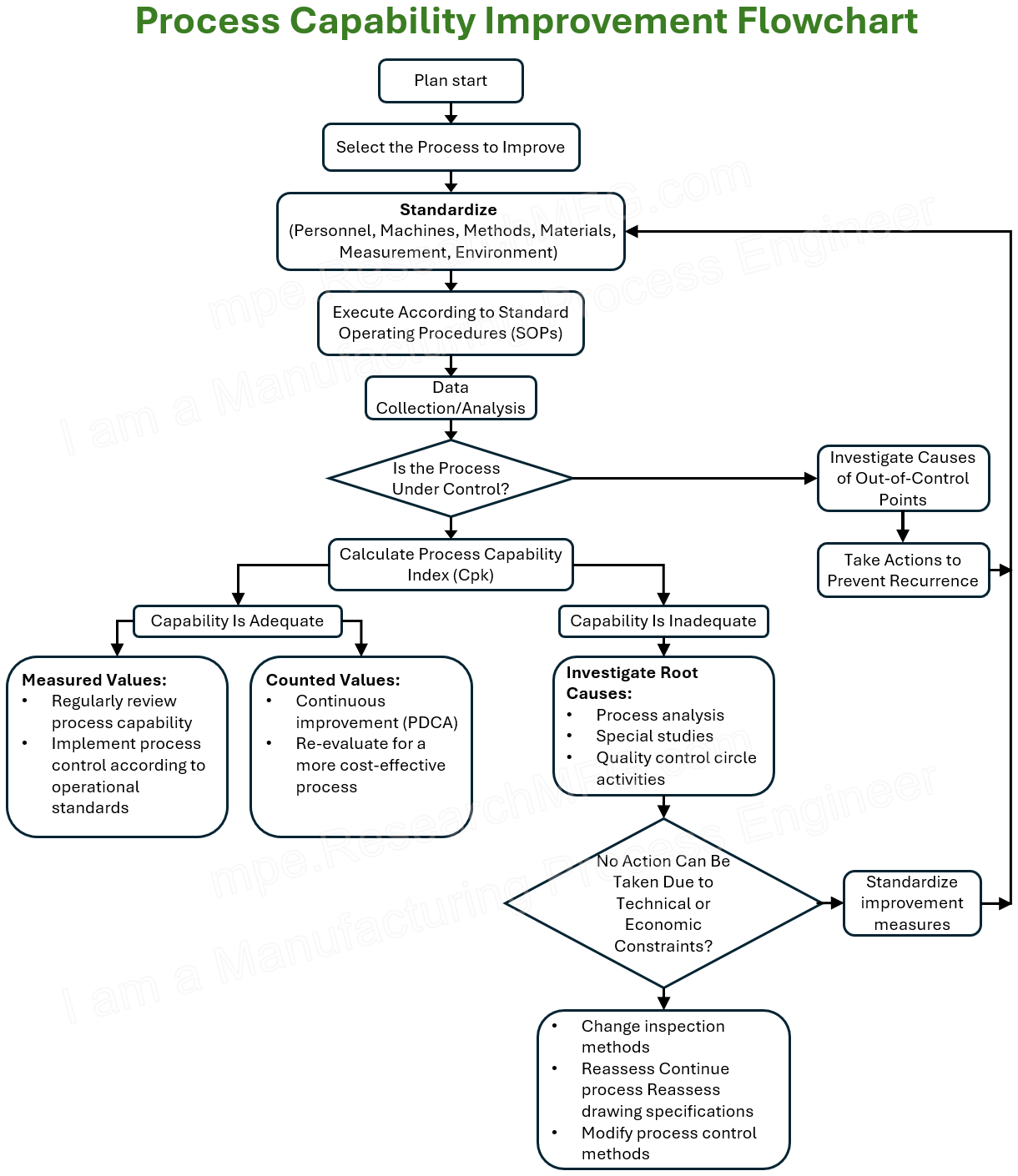

Personally, Workingbear think this process capability improvement flowchart is quite well-organized, so I cleaned it up a bit and decided to share it with everyone.

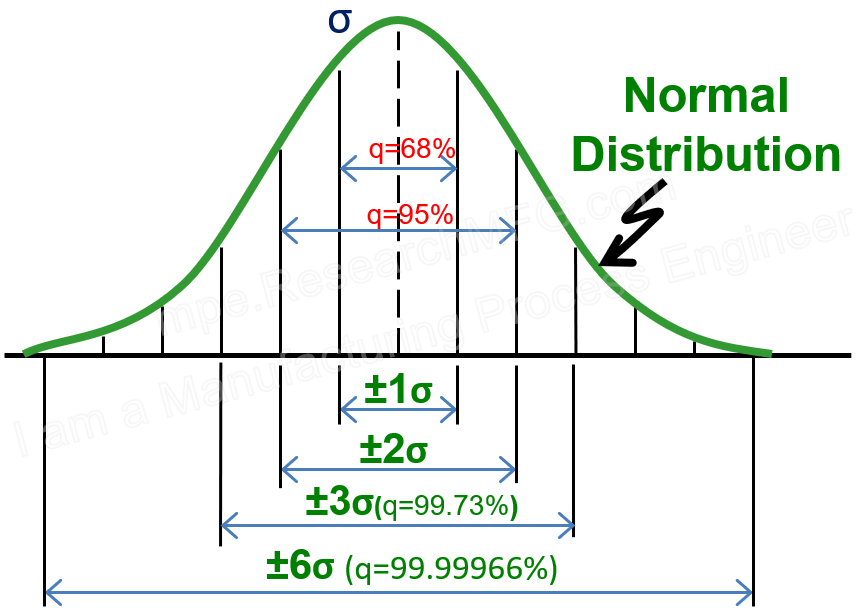

Please note: Before implementing Statistical Process Control (SPC), the process conditions must first be quantified. In other words, you need to find a way to turn the factors that affect product quality into measurable or countable data.

Counting refers to things that can only be tallied individually, like the number of defects or solder balls.

Measuring, on the other hand, involves continuous data like weight, speed, or temperature.

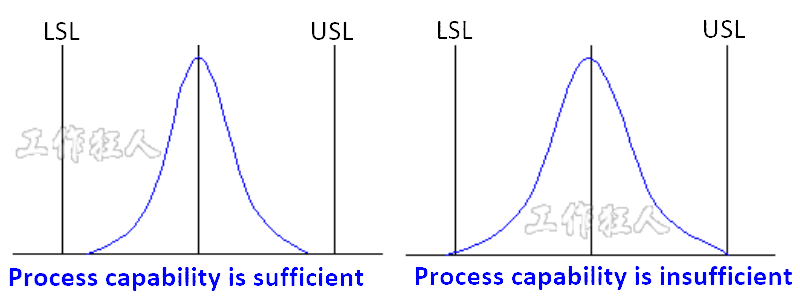

Also, keep in mind that SPC should only be carried out when the process is stable—meaning the Cpk has reached an acceptable level. If you try to apply SPC to a process that’s constantly in firefighting mode, it will only add unnecessary burden to the engineers and won’t help improve or maintain quality at all.

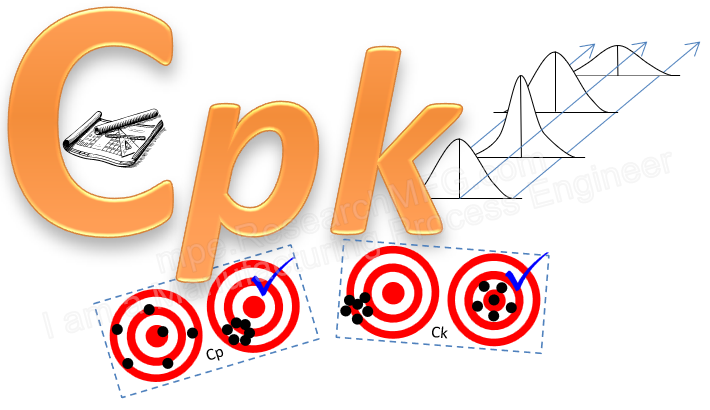

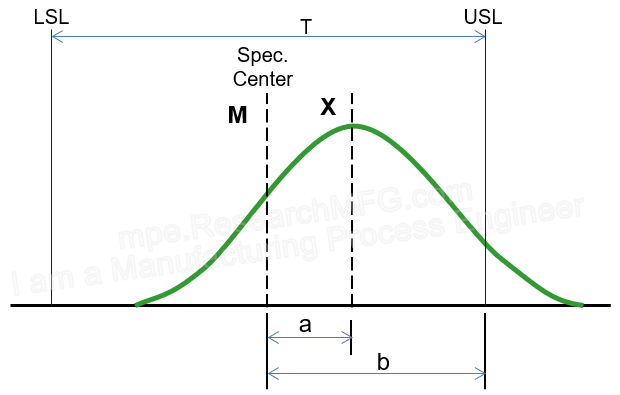

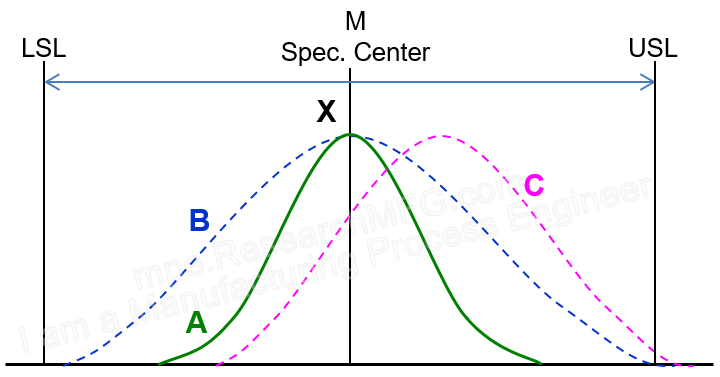

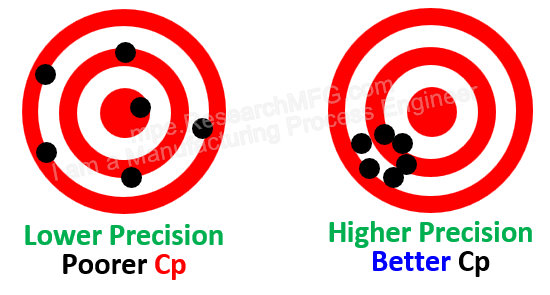

》Overview and Explanation of SPC, Cpk, and Process Capability

About Statistical Process Control (SPC):

Leave a Reply