What Is Ck or Ca?

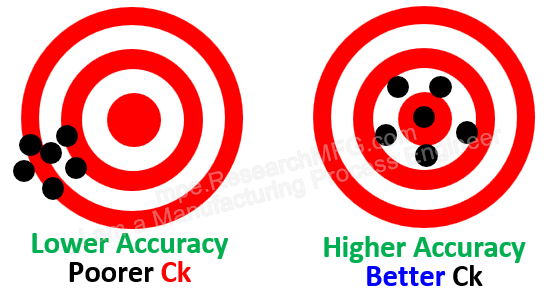

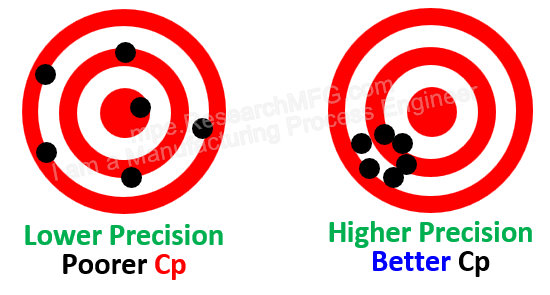

Ck, which some people now refer to as Ca (Accuracy), represents how close a process output is to the target value. Using a target-shooting example: if someone fires six bullets and all land near the bullseye, the Ck value is good (meaning low), because the average result is close to the center of the specification — a direct hit.

Some believe “Ca” is a better name because “Accuracy” clearly describes this concept. Others stick with “Ck,” and honestly, it’s a matter of preference. Workingbear thinks both are acceptable, but since the concept of Cpk originated or at least became popular in Japan, there’s a cultural nuance to the naming. In Japanese, Ck is derived from the word “かたより” (Katayori), which translates to “bias” or “deviation from center.”

While “Ca” does make sense linguistically as it stands for “Accuracy,” changing “Ck” to “Ca” would also logically suggest renaming “Cpk” to “Cpa,” which would feel a bit awkward since most people are already familiar with “Cpk.” That’s why on Workingbear’s blog, we’ll keep using “Ck.”

Ck Formula and Explanation

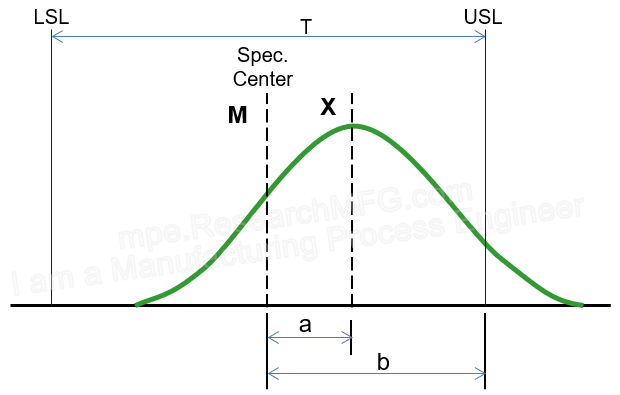

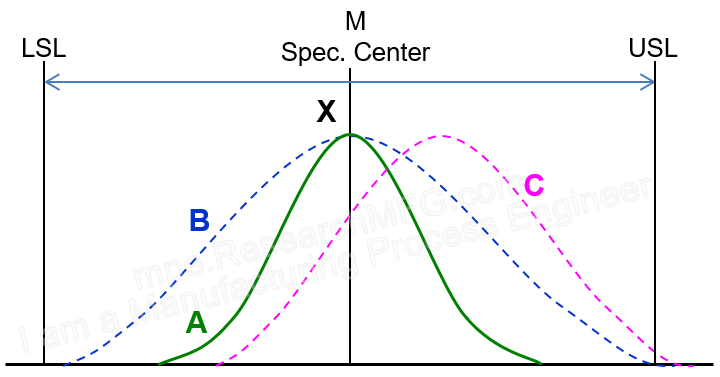

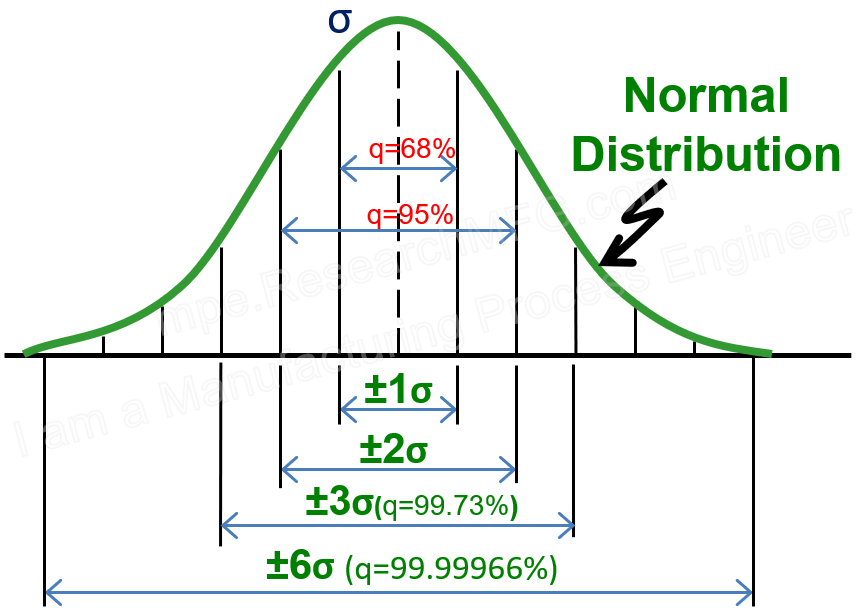

Ck=a/b=|(M-X)|/(T/2)

a=|M-X|: This is the absolute distance between the target center value (M) and the actual average value of the process (X). The result must be a positive number, which is why the absolute value is used. M: Target center of the specification.

X: Actual average (mean) of the produced data.b=T/2: Half of the total specification width T: Total tolerance or specification width (Upper Limit – Lower Limit)

So in simple terms, Ck = |(M – X)| / (T / 2) tells us how far the process center (X) deviates from the target center (M), expressed as a proportion of half the total specification width.

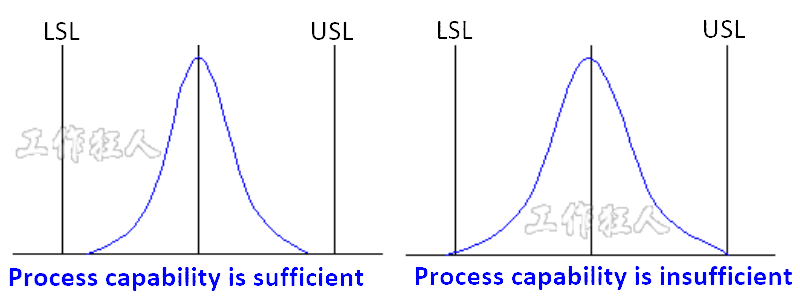

The smaller the Ck value, the closer the process mean is to the center of the spec — meaning better accuracy. When Ck = 0, it means the average of all measured results falls exactly on the spec center. But be careful — this doesn’t mean every part is perfect or centered, just that the average is. So using Ck alone to judge quality could be misleading. (Be sure to also check out the articles on Cp and Cpk for a more complete picture.)

| So, to sum up: | ||

| While | Ck=0 | The process center is perfectly aligned with the spec center. |

| While | Ck=1 | The process center has shifted exactly halfway across the spec — meaning the mean is sitting right on the upper or lower limit. |

Ck Evaluation Guidelines

|

Grade |

Ck Range |

|

Interpretation |

||||

|

A |

Ck |

≦ |

12.5% |

|

Excellent, keep it up. | ||

|

B |

12.5% |

< |

Ck |

≦ |

25.0% |

|

Acceptable, but could be improved to A-level. |

|

C |

25.0% |

< |

Ck |

≦ |

50.0% |

|

Operators may have misread the spec or skipped steps. Training and review needed. |

|

D |

50.0% |

< |

Ck |

|

Urgent action required. Review root causes and stop the line if necessary. | ||

》Overview and Explanation of SPC, Cpk, and Process Capability

Related Posts:

Leave a Reply