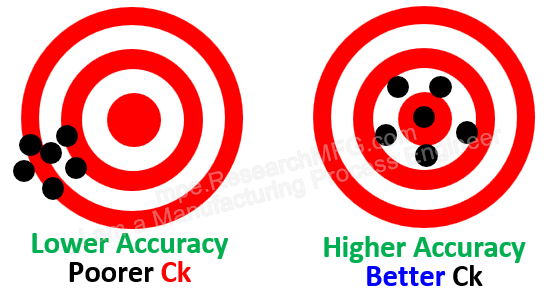

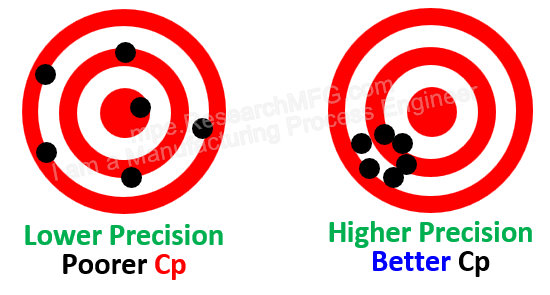

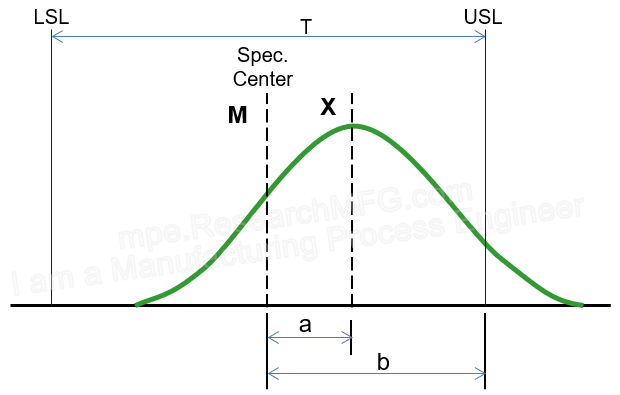

Process capability refers to the ability of a production process to consistently produce products that meet quality requirements under stable and fixed production conditions. To understand process capability, there are at least two key aspects we need to consider:

A manufacturing process’s capability is influenced by many factors, starting from product design, including materials, machines, equipment, methods, operator skills, inspection equipment, inspection methods, and the skill of the inspectors. Any changes in these factors can more or less affect process capability.