Why is it necessary to partially increase the solder paste volume in SMT soldering?

To meet the demands of smaller and thinner electronic component designs, stencils are made as thin as possible to precisely control the tiny solder paste printed on the PCB.

However, this creates a challenge when smaller and larger electronic surface-mounted devices (SMDs) need to be mounted on the same board. The stencil’s thinness limits the amount of solder paste that can be deposited, and extending the stencil aperture over the pad size is still not yet enough to fill the necessary volume of solder. To provide sufficient solder paste volume for larger components, as well as for HTD components, EMS has implemented the PIH (Paste in Hole) process.

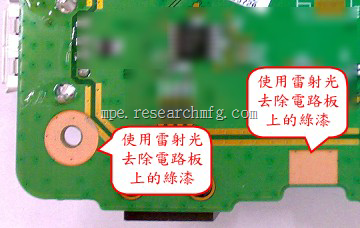

As an engineer in the electronics manufacturing industry, have you ever encountered the need to rework a printed circuit board (PCB) to remove the solder mask? If so, how did you approach this problem?

As an engineer in the electronics manufacturing industry, have you ever encountered the need to rework a printed circuit board (PCB) to remove the solder mask? If so, how did you approach this problem? The company’s approach to establishing and maintaining long-term working relationships involves creating and monitoring mutual performance expectations and measurements. The use of performance metrics, constructive feedback, and prompt corrective action by both the supplier and customer is essential for achieving continuous process improvement.

The company’s approach to establishing and maintaining long-term working relationships involves creating and monitoring mutual performance expectations and measurements. The use of performance metrics, constructive feedback, and prompt corrective action by both the supplier and customer is essential for achieving continuous process improvement. Improving the solderability of BGA (Ball Grid Array) packages is always a big challenge for the SMT (Surface Mount Technology) process. Fine pitch BGAs (with a ball pitch less than 0.8mm) are particularly difficult to solder onto the PCB. Additionally, inspecting the soldering result is challenging because the solder joints are hidden under the BGA body, and sometimes even 2D X-Ray inspection is insufficient. (5Dx or angle rotation X-Ray might be able to inspect BGA soldering quality, but these methods are expensive.)

Improving the solderability of BGA (Ball Grid Array) packages is always a big challenge for the SMT (Surface Mount Technology) process. Fine pitch BGAs (with a ball pitch less than 0.8mm) are particularly difficult to solder onto the PCB. Additionally, inspecting the soldering result is challenging because the solder joints are hidden under the BGA body, and sometimes even 2D X-Ray inspection is insufficient. (5Dx or angle rotation X-Ray might be able to inspect BGA soldering quality, but these methods are expensive.) Do you know how vendor ensure that their products are not damaged during shipping due to handling by transporters or delivery personnel? Reputable vendors put effort into designing and selecting suitable packaging materials for shipping to ensure the quality of their products. This article will introduce how vendor test whether their cardboard packaging meets general shipping requirements.

Do you know how vendor ensure that their products are not damaged during shipping due to handling by transporters or delivery personnel? Reputable vendors put effort into designing and selecting suitable packaging materials for shipping to ensure the quality of their products. This article will introduce how vendor test whether their cardboard packaging meets general shipping requirements.