A user asked: “During the SMT process, PCBs often warp or bow after going through reflow high temperature. In severe cases, this can lead to defects like insufficient solder joints or tombstoning. How can we prevent and solve this issue?”

To be honest, the reasons behind PCB warping and bowing may vary, but in the end, it all comes down to one key factor—when the stress applied to the PCB exceeds the material’s ability to withstand it. If the PCB experiences uneven stress or different areas of the board have varying resistance to stress, warping and bowing will occur.

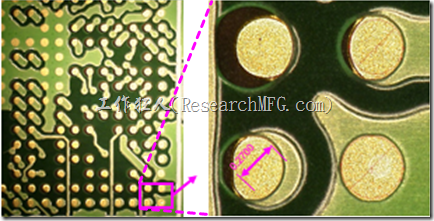

Recently, our company started a new project, and the R&D team has been pushing PCB layout requirements to the extreme. As PCBs size get smaller, the

Recently, our company started a new project, and the R&D team has been pushing PCB layout requirements to the extreme. As PCBs size get smaller, the