In my previous post, I mentioned that our company once used metal domes without dimples as the keypad contact solution—similar to what’s used in some cell phones. However, we soon ran into a problem: the keypads were not sensitive enough when pressed.

We eventually solved this issue by switching back to metal domes with dimples, and still achieved a 1,000,000-cycle finger press lifetime.

What We Found During Failure Analysis for Keypad Insensitivity

Our failure analysis revealed two major causes behind the keypad insensitivity issue:

-

Foreign contamination, such as dust and fibers, which I mentioned in the previous article.

-

Oxidation appearing on the ENIG (Electroless Nickel Immersion Gold) surface of the PCB pads.

We discovered that some oxidation particles looked like phosphorus (P), which likely came from the PCB base material. Phosphorus is one of the key elements used in the ENIG process. Unfortunately, it’s impossible to completely remove it from the board; we can only minimize its presence.

How the Defect Affected Keypad Performance

These contamination and oxidation particles are non-conductive, which prevents the metal dome from properly contacting the PCB pad when the key is pressed lightly.

When more force is applied, the particles are crushed, allowing the dome to make contact with the pad and activate the keypad function. This explains why some keys required extra pressure to work.

To reduce this problem, we started cleaning both the PCB gold pads and the metal domes before keypad assembly. This helped improve the yield rate—but it didn’t eliminate the issue completely.

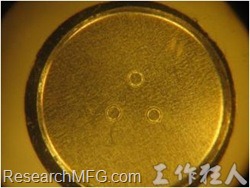

PIcture show 3-dimple metal dome design.

The 3-Dimple Metal Dome Solution

To fully fix the problem, we decided to switch to a 3-dimple metal dome design. Compared to the traditional single-dimple type, the 3-dimple version distributes the pressing force more evenly across the pad.

This helps prevent damage to the PCB gold pads while maintaining excellent tactile feedback.

The results were impressive:

-

The keypad sensitivity issue was completely resolved.

-

The new design passed environmental testing.

-

No keypad sensitivity defects were reported in production.

-

The domes successfully passed the reliability test, enduring over 1,000,000 press cycles without failure.

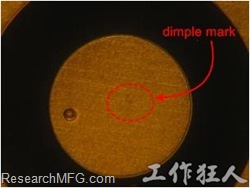

After testing, the gold pads showed only slight marks even after one million cycles, and all functions remained normal.

Picture show gold pad after 1,000,000 cycles of finger press test with 3 dimples metal dome. Only a slightly mark on the gold pad and all function OK.

Summary: Why the 3-Dimple Design Works

✅ No more keypad sensitivity issues in production.

✅ Contamination and oxidation effects can be ignored.

✅ Passed environmental and reliability testing.

✅ Achieved 1,000,000+ press cycles.

Common Metal Dome Designs in the Market

There are generally four common types of metal dome dimple designs available today:

-

Single-dimple dome – one dimple at the center.

-

Three-dimple dome – three dimples positioned in a triangle pattern.

-

Four-dimple dome – one center dimple plus three arranged in a triangle.

-

Five-dimple dome – one center dimple plus four arranged in a square pattern.

Any of these designs can potentially help resolve keypad sensitivity issues, depending on your product requirements and test results.

Related Posts:

![[Case Study] Troubleshooting a Customer Complaint – Keypad Malfunction Caused by Oil & Powder Contamination on the PCB [Case Study] Troubleshooting a Customer Complaint – Keypad Malfunction Caused by Oil & Powder Contamination on the PCB](https://mpe.researchmfg.com/wp-content/uploads/2025/Oil_on_PCB_summary-mpe.jpg)

it has been 10 years since this Post was published. I just found it. Maybe is a long shot but, hopefully you could read this. Was there and specific dimple height you tried? what was the diameter of the circular Metal dome you used? Thanks. Mechanical Eng- Detroit.

mauricio,

Well, it was a design from a long time ago, so I don’t have the detailed dimensions anymore. I’d recommend contacting the metal dome suppliers to get the dimple dimensions.