CTE (Coefficient of Thermal Expansion) refers to how a material’s geometric properties change as its temperature rises or falls due to thermal expansion and contraction. In practical applications, CTE is divided into two main categories:

- Coefficient of Linear Thermal Expansion – Applies to solids

- Coefficient of Volume Thermal Expansion – Applies to gases

Understanding Thermal Expansion and Contraction

When an object is heated, it expands, and when it cools down, it contracts. This happens because atomic vibrations increase with temperature, causing the material to expand. Conversely, when the temperature decreases, atomic vibrations slow down, leading to contraction.

Most materials in nature follow this principle. However, some substances, such as water (below 4°C), antimony, bismuth, gallium, and bronze, behave oppositely within certain temperature ranges. For example, water expands when it freezes instead of contracting. This is why you shouldn’t store canned or foil-packaged beverages in the freezer—the expanding ice can cause the container to burst.

Real-Life Examples of Thermal Expansion

1️⃣ Roads and Bridges – Roads made of cement have expansion joints at regular intervals to prevent buckling in hot weather. When driving over these joints on a bridge or concrete road, you might hear a “thumping” sound as the wheels pass over them.

2️⃣ Railway Tracks – If you closely examine railway tracks, you’ll notice they also have gaps between sections to allow for thermal expansion. Without these gaps, heat-induced expansion can cause tracks to bend and warp, as shown in the image below (source: Wikipedia).

3️⃣ Ping Pong Ball Fix – If a ping pong ball gets dented, placing it in hot water can restore its original shape because the air inside expands.

4️⃣ Pipes and Gas Lines – Many water pipes and gas pipelines are intentionally bent into circular or U-shaped loops to absorb expansion and contraction, preventing cracks or leaks.

How CTE Affects PCBs: Z-Axis CTE, α1 (alpha 1)/z-CTE, and α2 (alpha 2)/z-CTE

Almost every material in the world expands or contracts with temperature changes, and PCBs are no exception. While PCBs follow the general principle of thermal expansion and contraction, their CTE (Coefficient of Thermal Expansion) behaves differently in different directions.

-

In the X and Y directions, CTE is relatively low (around 12–15 PPM/°C) because the glass fiber weave constrains expansion.

-

In the Z direction (board thickness), there is much less constraint, leading to a higher expansion rate:

- α1/z-CTE (below Tg) is typically around 55–60 PPM/°C.

- α2/z-CTE (above Tg) is even larger.

-

Sometimes, “α” (alpha) is written as “a”, so you may also see a1/z-CTE and a2/z-CTE in technical documents.

What Do α1-CTE and α2-CTE Represent in CTE Testing?

To measure Z-axis CTE, the most common method is Thermal Mechanical Analysis (TMA). This test provides two key values:

- α1-CTE – The thermal expansion coefficient below the glass transition temperature (Tg).

- α2-CTE – The thermal expansion coefficient above Tg.

This distinction is crucial because PCBs experience different thermal behaviors before and after reaching Tg.

Why Is α2/z-CTE Critical for Lead-Free PCB Assembly?

Most lead-free PCBs use Tg150 materials, while IC substrates often use Tg170 materials. However, both are much lower than the melting point of SAC305 lead-free solder (217°C) and typical reflow peak temperatures (240–250°C).

Because PCBs experience significant thermal stress above Tg, the α2/z-CTE value is the most important when evaluating PCB reliability in high-temperature environments.

According to IPC-4101, the recommended CTE limits are:

- α1/z-CTE should not exceed 60 PPM/°C.

- α2-CTE should not exceed 300 PPM/°C.

Because the CTE of copper in PCB plated through-holes (PTHs) and pads is around 16–18 PPM/°C, a large mismatch between copper CTE and α2-CTE of the PCB can lead to several reliability issues:

- Cracking in the plated hole walls

- Copper annual pad lifting from the PCB

- Localized tearing

- Popocorn Effecot (delamination) for Board

Additionally, the overall Z-axis CTE from 50°C to 260°C is another critical factor. According to IPC-4101, the recommended maximum Z-axis expansion limits are:

- 4% for standard Tg materials

- 3.5% for mid-Tg materials (Tg ≥ 150°C)

- 3% for high-Tg materials (Tg ≥ 170°C)

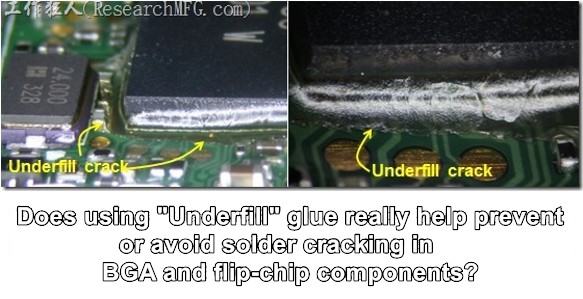

Does PCB CTE Affect Solder Joints?

In theory, excessive CTE in FR-4 laminates could impact solder joint reliability, as it may cause stress on the solder connections between components and PCB pads. However, solder has a certain level of elasticity and vibration resistance, so CTE-related solder joint failures are rarely reported.

Most electronic products undergo high-low temperature cycling reliability tests before release, so concerns about FR-4 CTE affecting solder joints are unnecessary. Instead, a more critical issue is the cooling rate after peak reflow temperature. If the cooling is too fast, it may lead to solder joint cracking.

Interested in reflow profile?

If you’re interested in how solder behaves in a reflow oven and how temperature profile settings affect solder performance, you can check out these articles.

- Temperature Environmental Cycle Profile

- RSS or RTS? Which SMT Profile Should You Choose?

- SMT Reflow Soldering Temperature Profiles Explanation and Precautions

Related posts:

Leave a Reply