Workingbear has spent quite some time in the industry, but only recently heard the term SKU for the first time. In practice, people usually just say “SKU”. At first, Workingbear had no idea what SKU meant—not even how to spell it. Asking colleagues didn’t help either. Everyone just said they kept hearing this term from the U.S. headquarters.

Maybe it’s because the company has hired many new people recently, bringing in new terminology. Most of the time, SKU comes up in sentences like, “How many SKUs are included in this pilot run?” For example, BT + Wi-Fi + 16GB memory is one SKU, GPRS + 3G + 32GB memory is another SKU, and LTE + Wi-Fi + 64GB memory is yet another SKU. From this, you can roughly tell that SKU refers to different product configurations.

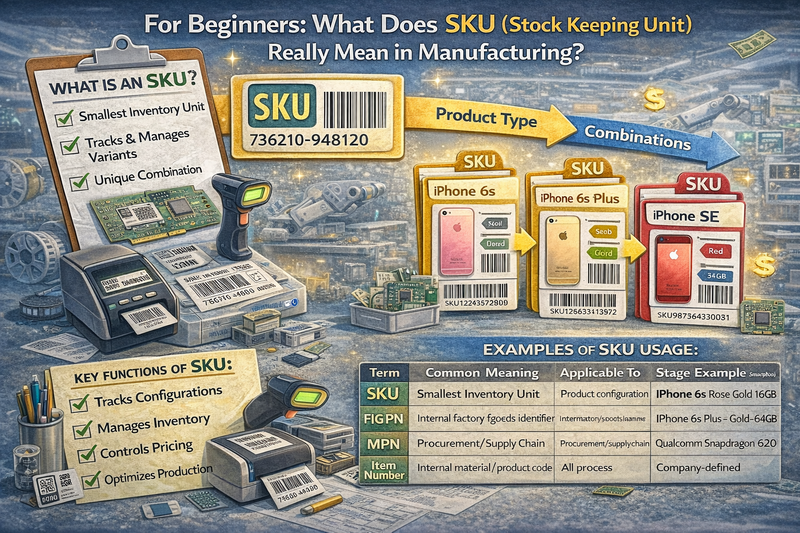

After quietly asking a colleague in the U.S., Workingbear finally learned what SKU stands for. A quick search showed that SKU (Stock Keeping Unit) means the smallest unit that can be independently tracked, managed, and sold in inventory. In consumer electronics manufacturing (such as smartphones and tablets), an SKU usually represents a specific finished-product configuration—such as a combination of color, memory size, and network features. Inside a factory, each SKU typically maps to a unique finished-goods part number (FIG PN) and its corresponding BOM.

Using the iPhone as an example, one SKU could be iPhone 6s + Rose Gold + 16GB, while another SKU could be iPhone 6s Plus + Gold + 64GB. In other words, each SKU represents a version of the product that customers can actually buy.

Note: The meaning of SKU can vary slightly by industry or company. Some B2B manufacturers prefer to use terms like Finished Goods Part Number or Item Number, while SKU is more common on the retail or e-commerce side. However, in EMS or ODM mobile phone factories, phrases like “How many SKUs are in this pilot build?” are extremely common.

In practice, an SKU represents the smallest unit a company uses to track, manage, and sell products. As product options became more diversified—different configurations, colors, memory sizes, and regional variants—the traditional idea of managing products only by “product type” was no longer sufficient. SKU-based management emerged as a practical solution, allowing companies to precisely control inventory, pricing, and production across highly customized product offerings.

There is a clear difference between product type and SKU. For example, iPhone product types might include iPhone 6, iPhone 6s, iPhone 6 Plus, iPhone 6s Plus, and iPhone SE. However, when customers place orders, they don’t just choose the product type—they also specify color, memory size, and sometimes even bundled accessories. Clearly, “product type” alone is no longer sufficient to meet modern ordering requirements.

As a result, the concept of SKU became widely adopted. Thanks to computer systems and easy data lookup, SKUs are now heavily used in e-commerce product management. Over time, SKU has also come to mean a unique product identifier—each product corresponds to one unique SKU number. For example, when you buy something online, the system always assigns that product a unique ID, which is essentially its SKU.

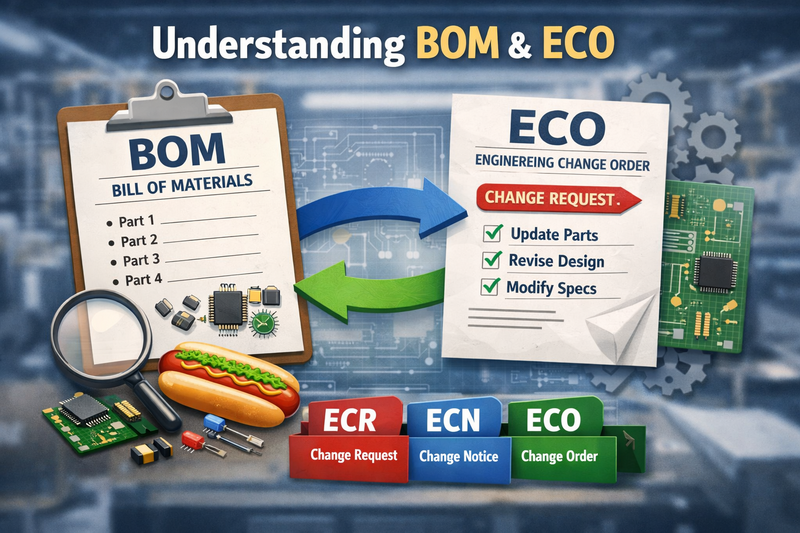

When you apply this concept to factory production, it becomes clear that each SKU corresponds to a finished-goods BOM combination inside the factory.

Recommended reading: Explaining the Relationship Between BOM, AML, AVL, and MPN

So when people say, “This pilot run includes several SKUs,” what they really mean is, “We are going to produce several different finished-goods part numbers.” All of these combinations are managed through BOMs, and each SKU is built using a specific BOM configuration.

From a manufacturing perspective, SKUs make it easier to accurately track output, inventory, and cost for different configurations. However, having too many SKUs increases complexity—BOM maintenance becomes harder, material preparation is more difficult, and line changeovers during pilot runs become riskier. This can eventually lead to configuration mistakes. That’s why it’s recommended to control the number of SKUs or use modular designs to reduce variation.

Here’s a quick comparison of related terms:

| Term | Common Meaning | Applicable To | Stage Example (Smartphone) |

|---|---|---|---|

| SKU | The smallest inventory unit | product configuration (finished goods, sales side) | iPhone 6s Rose Gold 16GB |

| Finished Goods Part Number (FIG PN) | Internal factory identifier for finished products | production/BOM | Often the same as or mapped to SKU |

| MPN | Manufacturer Part Number for raw materials or components | procurement/supply chain | Qualcomm Snapdragon 820 |

| Item Number | Internal material or product code | used across processes | Company-defined |

Extended topic:

SKU is even more flexible in retail. Take canned soda as an example. In a supermarket, you may see single cans sold individually, or packs of four or six cans sold together. To support promotions, stores often give different prices depending on the quantity purchased. If everything were managed only by “product type,” every can would have the same unit price, and promotions would be harder to manage in the system.

With SKUs, a single can, a four-pack, and a six-pack can each have a different SKU and different pricing. The downside is that sometimes a six-pack may not be cheaper than buying single cans, because each SKU is priced independently. This can usually be fixed by adjusting the system logic, such as grouping the same product type together during promotions.

As ERP and MES systems become more integrated, modern SKUs are often directly linked to barcodes, RFID, or QR codes, enabling more accurate and real-time tracking.

In short, in consumer electronics manufacturing, SKU is a critical bridge connecting design, production, and sales. Understanding what SKU really means helps teams manage diverse product lines more efficiently. Feel free to share how your company defines or manages SKUs in the comments.

Related Posts:

![[Case Study] Troubleshooting a Customer Complaint – Keypad Malfunction Caused by Oil & Powder Contamination on the PCB [Case Study] Troubleshooting a Customer Complaint – Keypad Malfunction Caused by Oil & Powder Contamination on the PCB](https://mpe.researchmfg.com/wp-content/uploads/2025/Oil_on_PCB_summary-mpe.jpg)

Leave a Reply