SPI stands for Solder Paste Inspection. If we’re talking about the actual inspection equipment, people usually add “machine” after SPI. But in most cases, when you mention SPI in an SMT factory, everyone just assumes you’re talking about the inspection machine.

So what’s the real purpose of SPI? What exactly can it do for us? And why are more and more SMT lines adding SPI machines these days?

80% of SMT Defects Come from Solder Paste Printing

Workingbear once heard this surprising fact: around 80% of SMT defects come from solder paste printing issues. If that’s true, doesn’t it make perfect sense to put an SPI checkpoint right after solder paste printing and before components placement? That way, any PCB with bad solder paste printing can be caught before components are placed. This should improve yield, right? The answer is yes. The key is using SPI effectively to catch printing defects, then tracing back to understand why the solder paste printing went wrong in the first place and fixing it.

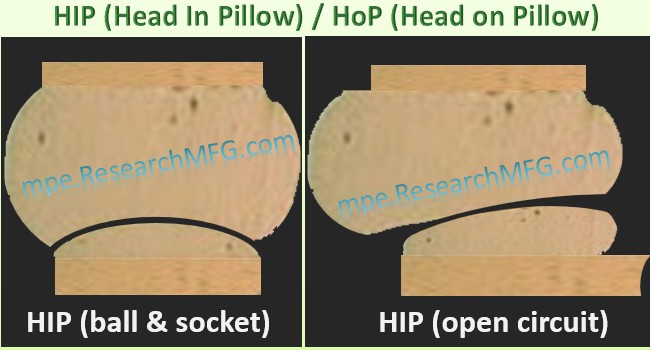

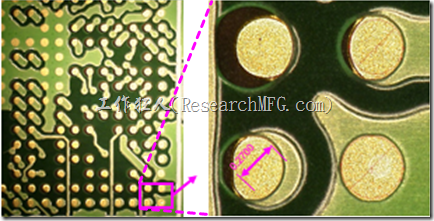

This is especially important now that we use smaller parts like 0201 chips and bottom-terminated parts like BGAs. These components are extremely sensitive to solder paste volume and placement accuracy. If you can catch a paste-printing issue before reflow oven, it saves you time and money. Waiting until after reflow means you’ll need rework with a soldering iron or even advanced repair tools, which risks damaging the PCB or components.

SPI vs AOI – Similar but Different

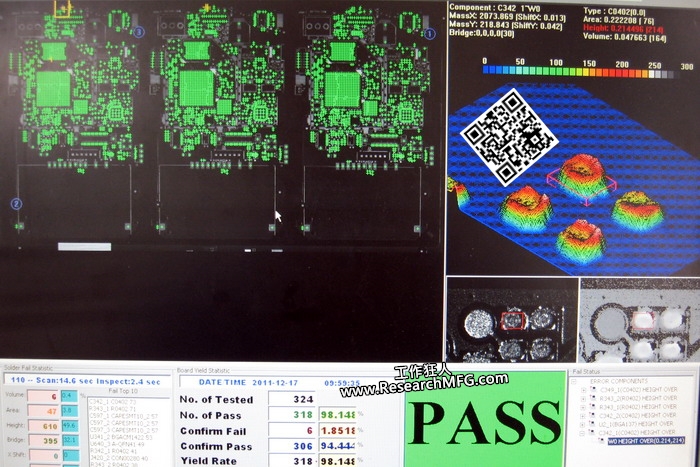

Think of an SPI machine as something similar to AOI (Automated Optical Inspection) in SMT lines, which is usually placed after reflow. Both use optical imaging to inspect soldering quality. The difference is that SPI adds a laser measurement system to check solder paste height and thickness.

But just like AOI, SPI also needs a reference. You first scan a sample board that passes visual inspection and set it as the Golden Sample. Later boards are compared against this standard. Of course, this creates false calls, especially at the beginning of a new product run. That’s why engineers have to fine-tune parameters until the false-call rate is under control. In other words, buying an SPI machine doesn’t mean you can just plug it in and expect results. You still need skilled engineers to set up and maintain it.

Most SPI machines can also read Gerber and CAD files, but in practice, there are always slight mismatches with the real PCB that need manual adjustment.

What Can SPI Machines Actually Check?

An SPI machine can measure things like:

-

Solder paste volume

-

Solder paste shape

-

Height of the paste deposits

-

Area/volume ratio

-

Flatness and consistency

-

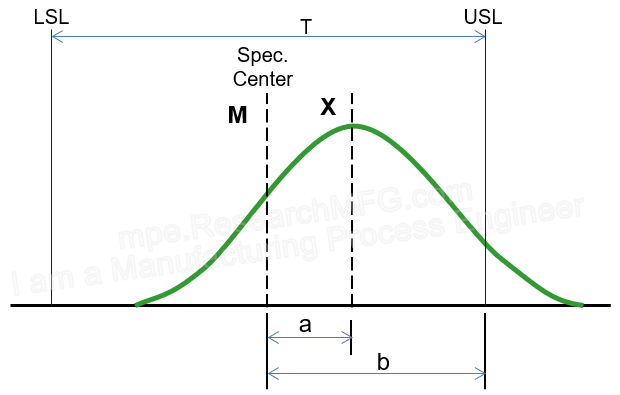

SPC data to track process capability

And it can detect defects such as:

-

Misalignment (shifted paste)

-

Height issues (peaking)

-

Bridging between pads

-

Damaged or missing solder paste

But at the end of the day, remember this: SPI is just a tool. If you only use it as a red/green light and ignore its data, it won’t help improve quality—it’ll just slow down production. The real value comes from using SPI feedback to adjust your solder paste printing process and fix problems at the source.

With technological advancements, SPI systems can now leverage artificial intelligence (AI) and big data integration to achieve more precise defect detection and classification, with real-time feedback to the front-end solder paste printing process to enhance process capability and reduce defect rates. Consult relevant personnel to explore software upgrades for improved production efficiency.

So here’s the real question: Is your company’s SPI machine actually improving yield, or is it just sitting there as a fancy decoration?

Here are two YouTube videos that show you what a solder paste inspection (SPI) machine can do, and how SPI sends feedback results back to the solder paste printer.

Extra Thought

If SPI is so useful, why don’t all companies see big quality improvements after installing it?

Here’s the thing: “A good tool is only as good as the person using it.” If you have great equipment but don’t know how to use it, it’s wasted. It’s like finding a rare weapon in a video game, only to realize your character isn’t high enough level to equip it. Awkward, right?

SPI machines don’t magically improve quality. They simply catch solder paste issues based on the rules you set. If you don’t know how to take SPI data and feed it back into your printing process, you’ll either end up with constant red alarms that stop production, or no alarms at all.

👉 Suggested reading: How do you set SPI control parameters? And how should solder paste thickness limits be defined?

How does your company’s SPI perform its functions? Feel free to leave comments and discuss.

Related Posts:

Leave a Reply