From what I remember, one of the earliest and most frequent requests for tumble testing came from Motorola. Since some of Motorola’s mobile phones and products were designed for military use, their reliability and quality standards were exceptionally strict. However, this also meant higher design and production costs. I can’t help but wonder if this was one of the reasons Motorola eventually lost its competitive edge.

Workingbear strongly believes in maintaining high-quality standards, but over-engineering beyond practical use (over quality) can be a waste of resources. Take smartphones as an example—most people replace their phones every two years. Designing a phone to last five years is already impressive. Insisting on a 10- or 20-year lifespan might only make sense if it doesn’t significantly increase costs. Otherwise, companies need to seriously consider whether the extra investment is worth it.

Alright, let’s get to the point. The tumble test is essentially designed to simulate a product accidentally falling to the ground multiple times. Traditional drop tests (impact drop tests) typically assess the six faces and eight corners of a product. If additional testing is required, the eight edges can be included as well. These tests, whether performed on packaged or bare units, are mostly designed for desktop products, which have a relatively low chance of falling. The main goal is to simulate accidental drops during regular use, usually just once or twice.

However, mobile devices—especially smartphones—are constantly being handled. It’s easy for a user to accidentally drop a phone from their hands or even fling it out of their grip. These types of drops cannot be accurately simulated with standard drop tests, which is why the tumble test was developed.

Early tumble tests were designed to mimic a phone continuously rolling on the ground, with the worst-case scenario being a phone tumbling down a flight of stairs. The first crude testing method involved placing a phone in a pet exercise wheel, similar to what guinea pigs run in, and letting it spin continuously.

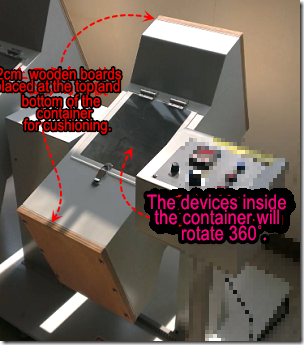

Later, industrial standards such as IEC 60068-2-31 were introduced. This standardized test uses a 500mm-high steel drum with a 3mm-thick steel plate at the bottom, cushioned by a 20mm-thick wooden layer for shock absorption. The drum rotates at 5–15 revolutions per minute, and the device inside falls from the top to the bottom with each half rotation, simulating repeated tumbles. The typical acceptance standard is 500 tumbles, equivalent to 1,000 individual drops.

Based on experience, the tumble test is far more demanding than a standard drop test. It not only reveals mechanical design flaws but also exposes weaknesses in poor soldering and loose electronic components. Workingbear believes that structural issues are relatively easy to fix—reinforcing key areas, increasing material thickness, or reducing sharp corners usually does the trick.

Solutions for BGA IC Detach and Solder Cracking Issues

One way to strengthen solder joints is by increasing the PCB pad size. If possible, reducing PCB deformation during testing through mechanical design adjustments is the best approach. If that’s not feasible, factories can apply underfill to enhance the BGA’s adhesion to the PCB. However, using underfill means higher material costs, longer production time, and more difficulty in future repairs.

Workingbear has encountered cases where even underfill couldn’t prevent BGA detachment. Initially, troubleshooting felt like running around blindly, but after discovering strain gauges, which measure stress-strain distribution during assembly and drop testing, problem-solving became much more efficient. While strain gauge equipment isn’t cheap, the consumable strain gauges themselves are relatively affordable.

Related Reads:

- [Case Study] Mechanical Design Improvements to Prevent BGA Solder Ball Cracking

- Preventing BGA Solder Joint Cracking: Strengthening Design from the Source

- How to Analyze, Diagnose, and Resolve Component Drop Issues on PCBs

Flip-Lock Connector Issues

This issue typically occurs in flip-lock connectors, where the actuator fails to stay locked. The first step is to check if the mechanical structure can support the connector to prevent the actuator from loosening. If that’s not enough, applying tape over the connector can help. As a last resort, adhesive can be used, but be cautious—glue can cause poor contact issues and make repairs more difficult.

Flip-lock connectors come in various locking mechanisms to secure FFC/FPC cables, including front flip, back flip, and slide lock designs, all intended to ensure a stable connection.

Related Reads:

- Flip-Lock and Right-Angle Flexible Circuit Connectors

Oscillator Failures

Oscillators are extremely fragile, so it’s common to secure them with hot glue or silicone adhesive. Another approach is to solder the entire oscillator body directly onto the PCB. However, when applying glue, be mindful that it may affect the oscillator’s frequency stability.

Large and Heavy Electronic Component Detachment

For large and heavy components, the first step is to increase the PCB pad size or use mechanical reinforcements to hold them in place. If that’s not sufficient, applying red glue (SMT adhesive) during the SMT process can improve stability. As a last resort, adhesive or epoxy can be used to secure the component permanently.

General Recommendations

The preferred approach is to first enhance strength through design improvements, as this doesn’t increase costs and provides the most reliable quality assurance. Only when design changes are insufficient should additional manufacturing processes and auxiliary materials be considered. However, keep in mind that extra materials and processes increase costs, may lack standardization, or introduce variability that could impact production quality.

👉 Feel free to share your company’s solutions so we can exchange insights and improve together!

▲ This is a video about the tumble test that I found online.

▲ At the 25-second mark, you can see the guinea pig-style tumble test that Workingbear mentioned.

▲ This guinea pig-style tumble test in the video is being used to test a suitcase.

Leave a Reply