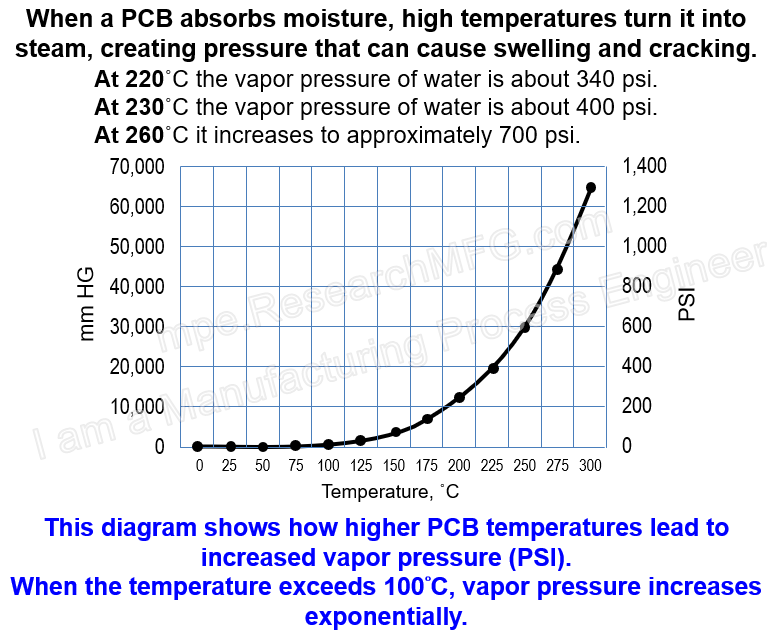

The Popcorn Effect in PCB and electronic components refers to the delamination (board cracking) or formation of bubbles when exposed to high temperatures during soldering. This phenomenon is similar to how popcorn pops—it happens because of trapped moisture inside. When heated, the internal moisture turns into steam, and as the temperature increases, the pressure from the steam rises. If this pressure exceeds the bonding strength of the component, PCB, or IC package, it causes a sudden expansion—just like a kernel turning into fluffy popcorn.