For many people, the first time they hear the term NPI, it feels a bit confusing. NPI stands for New Product Introduction, but just reading the name doesn’t make it much clearer. Is it some kind of sales role that introduces new products to customers? Not at all!

In reality, NPI is a bridge between the manufacturing plant and the R&D department. The core responsibility is to take a product designed by R&D and “introduce” or more accurately, drive it into mass production at the assembly factory.

Calling it an “introduction” might sound too gentle—it’s more like making sure the factory produces the new product. But factories still appreciate NPI, because without NPI there would be no new products to build, and without new products, there’s nothing to produce—which could mean no business at all.

During the R&D phase, a new product usually goes through several trial build stages, such as EVT (Engineering Verification Test), DVT (Design Verification Test), and PVT (Production Verification Test). Sometimes a single stage can have multiple trial runs.

(Related reading: Exploring EVT/DVT/PVT: Explaining the Three Crucial Validation Stages in New Product Development)

The NPI’s job is to coordinate all manufacturing resources, work with production control, and plan and track the trial build schedule. Most companies want their new products to hit the market as soon as possible—ideally before competitors launch something similar. It’s like HTC, Xiaomi, or Samsung trying to release a new smartphone before Apple announces the next iPhone.

Because of this, trial build timelines are often extremely tight. For example, in our company, if it’s a complete device build—from PCB fabrication to final enclosure assembly—the requirement might be to finish within a week or less. If it’s just PCB assembly, the target could be as short as three working days or even less.

From experience, the two biggest challenges during trial builds are unclear material status and frequent engineering changes.

New products often require new components the company has never used before. That means long lead times or issues with minimum order quantities (MOQ). At this point, strong support from the purchasing team is critical. They need to leverage the company’s buying power—or any possible method—to secure the shortest lead time and sample parts, sometimes even free samples.

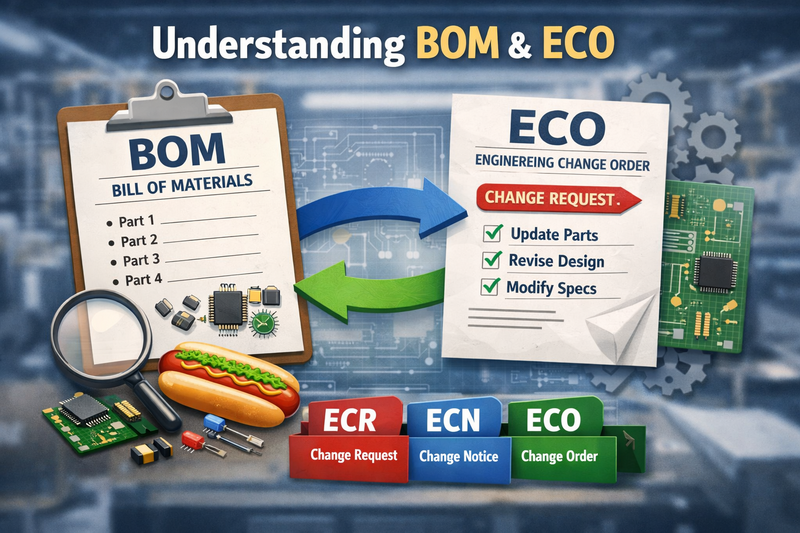

Frequent engineering changes can also make the material lead time problem worse. This usually ties back to the capability of the R&D team, which is a separate topic. One strong recommendation: all engineering changes should go through the company’s PDM (Product Data Management) system as ECOs (Engineering Change Orders). While it may feel cumbersome, this ensures quality and avoids unnecessary disputes when tracking engineering issues later.

Some companies even require NPIs to have a solid engineering background so they can flag potential production issues early when R&D designs new processes. This helps prevent designs that are impossible to mass-produce. NPIs may also need to push factories to improve their manufacturing capabilities to meet the demands of increasingly compact product designs—something that’s often a serious challenge for the factory.

Here’s Workingbear’s personal take on NPI:

- NPI, short for New Product Introduction, is the term for bringing new products into production. It can be a one-person role or an entire department. The team could include a new product project manager, new product parts purchaser, and new product engineers.

- In most companies, NPI usually just has a new product project manager. It’s a managerial role, so if you’re aiming for a manager position, it’s worth trying. You might even climb higher one day.

- You don’t necessarily need much engineering experience to be an NPI project manager—you can learn on the job. What’s most important is knowing how to work well with people.

- If you’re an NPI engineer, you’ll need to master a wide range of skills related to factory processes and R&D. You’ll mostly act as a technical manager—telling others what to do. But if you only talk without having real technical knowledge, people will keep their distance.

- If you want to learn and understand the entire process of a company—from R&D to production—this role is a good choice. Just remember: knowing a lot about many things often means you won’t be deeply specialized. You’ll know a bit of everything, but not in depth.

- If your manufacturing facility is a contract manufacturer (CM), you can usually speak more assertively. If it’s your company’s own factory, keep a humble and flexible attitude.

- Often, you’ll be working alone, having to persuade moody engineers and buyers to cooperate. A flexible attitude is key. Of course, if your company values this role highly and gives NPI real authority, that’s a different story.

- In our company, NPI has always been a tough and thankless job—when you do well, it’s “just your job”; when you mess up, it’s all on you.

Here’s an example of an NPI job description from a certain company:

- Coordinate process, manufacturing, and logistics for all product launch activities: prototype series, pre-series, full run test, and production release.

- Establish and track project timelines, including resource planning.

- Create and follow up on action plans.

- Work with the R&D team on product design and process design issues.

- Lead design reviews for the process team and ensure the product can be manufactured.

- Participate in manufacturing cost analysis and production cost calculations, including cycle time, efficiency, and labor.

- Analyze and address customer requirements, including manufacturing and process needs.

- Act as the technical interface between the customer and the company.

- Report project status in program review meetings.

- Update the operations manager on progress.

Here’s a quick rundown of the new product development phases:

-

EVT – Engineering Verification Test

In this stage, engineers build early samples so R&D can debug and check the design. The design is still rough and may have many problems—some parts might even be experimental. Engineers test different design options, fix issues, and make sure nothing in the specs is missing. -

DVT – Design Verification Test

This is the second stage. By now, the design should be mostly finalized. The main goal is to find and fix any remaining design or manufacturing issues, and make sure everything meets the required specifications and is ready to produce. -

PVT – Production Verification Test

Here, the design work is finished, and testing is complete. The purpose is to check if the manufacturing process works smoothly before starting mass production. This requires building a certain number of units, following the factory’s standard operating procedures for every step.

Related Posts:

Leave a Reply