Many component suppliers work extremely hard to get into certain companies as approved suppliers. Playing the “pretty salesperson card” is a common tactic—while engineers may appreciate it, most of the time it still doesn’t open the door. So where does the problem really lie? And how should sales actually approach this? This article looks at the topic of becoming a 2nd-source supplier purely from an engineer’s point of view. In reality, things can be even more complicated.

Becoming a component supplier to a system company is not necessarily difficult—but it’s not easy either. It’s easy if your product is in a seller’s market, where you’re the only one who can make it. In that case, customers come to you automatically, and you can even choose who you want to sell to—like some CPU vendors in the past.

But if your product is in a buyer’s market, where many suppliers can offer similar parts, then you’re competing on much more than price, quality, service, or even how attractive your sales team is. You’re also competing on timing, relationships, and—most importantly—patience.

Think about it from an engineer’s perspective. If you’re an R&D or process engineer working on a product that’s already in stable mass production, and everything is running smoothly, why would you want to change a component or a process? If the change goes well, most of the credit usually goes to procurement, not engineering. But if something goes wrong, engineers are the ones who have to clean up the mess—and sometimes it can be extremely stressful.

On top of that, before introducing an alternative component, engineers often have to revalidate product functions, processes, and sometimes even resubmit the product for certification. In many cases, the cost savings from switching to a cheaper component don’t even cover the revalidation cost. So why would anyone switch suppliers just because your part is slightly cheaper?

Seize the Right Two Opportunities to Successfully Become a New Supplier for System Companies

So when do component suppliers have a better chance of becoming a 2nd-source supplier? In my opinion, there are two key opportunities:

1. During new product development.

New designs often require new components. If you can get involved at this stage, you can avoid many revalidation headaches, and engineers are usually more open to trying new suppliers.

2. When existing products run into problems.

Because development cycles in electronics are short, issues after mass production are common. When problems arise, engineers are often eager to look for alternative components or solutions to resolve urgent issues.

When these opportunities appear, the relationships and service you’ve built over time finally pay off. That’s why, if you want to become a 2nd-source supplier, you should stay in regular contact and proactively share your new products and technologies with engineers.

Business requires patience and a long-term mindset. Once you become a 2nd-source supplier, if your product quality is solid, pricing is competitive, and service is reliable, becoming a primary supplier is only a matter of time.

Related Posts:

- Why Does Second-Source Qualification Always Fall into a Vicious Cycle?

- How Adding a Second Source (2nd Source) Can Create a Win-Win for Cost Reduction

- Why Second Sourcing Matters: Real Challenges and Practical Solutions in Electronics Supply Chains

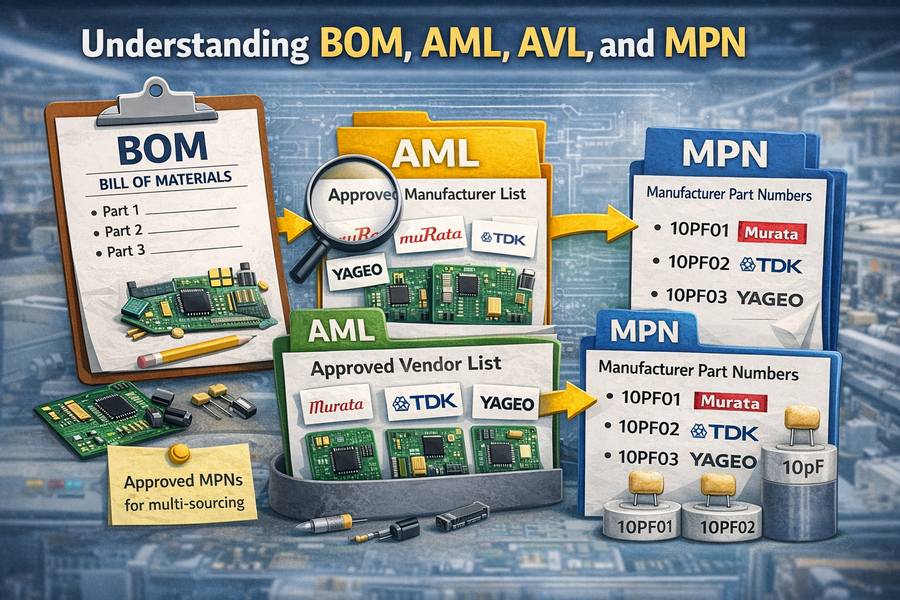

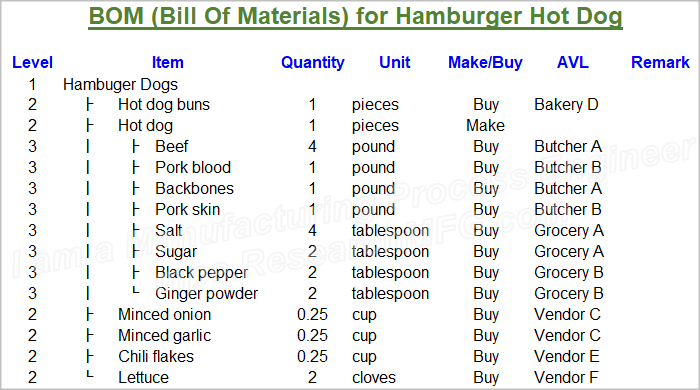

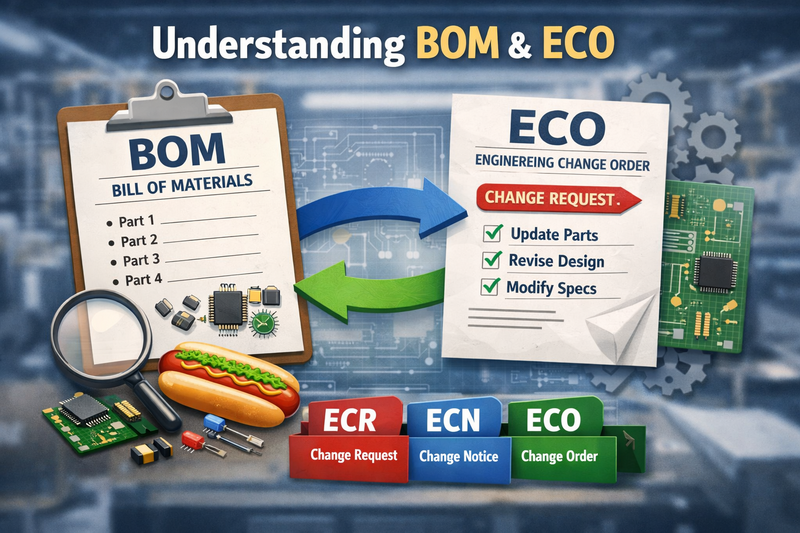

- For Beginners: What Is a BOM? How BOM Works with ECO, ECN, and ECR in Electronics Manufacturing

Leave a Reply