“Second-source” qualification usually means that a component has at least two qualified suppliers. The reasons for introducing a second source are straightforward: to deal with material shortages, handle EOL (End of Life) parts, reduce material costs, increase price negotiation leverage, replace underperforming suppliers, and improve overall product quality.

However, based on Workingbear’s personal experience, second-source qualification often becomes a tough and thankless task in most companies. This work is usually urgent and time-sensitive, yet a small mistake can lead to quality issues—and in serious cases, major financial losses. Unfortunately, top management often doesn’t pay much attention to what engineers are actually doing. They tend to focus only on short-term price reductions and selectively ignore the quality and risk associated with second sources.

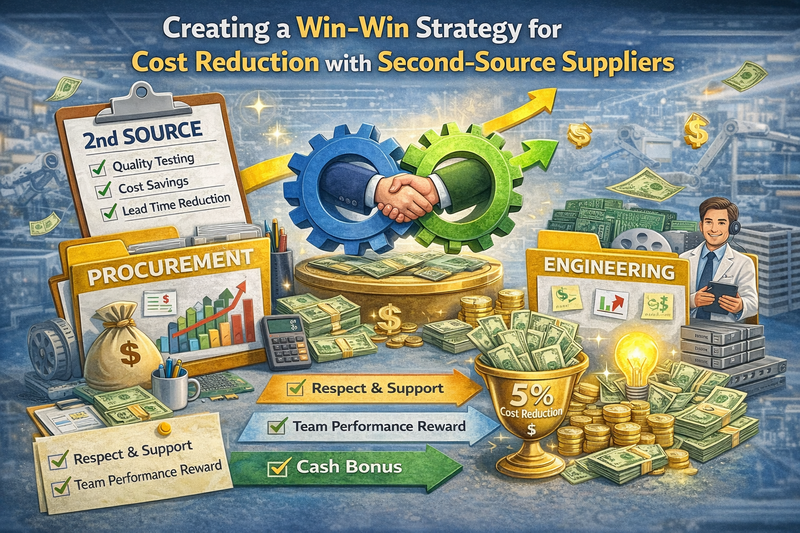

On top of that, almost all the credit for cost reduction usually goes to the procurement team, since price-cutting KPIs are often owned solely by purchasing. Engineers do all the hard work—reviewing specifications, running tests, validating parts—but no one really cares about the process. Management only asks, “When will the result be ready?” As a result, for the teams responsible for second-source qualification, it often feels like “doing it right is expected and unnoticed, but doing it wrong is unforgivable.”

(These pain points do have solutions. It really comes down to whether top management takes second sourcing seriously. Companies can also make second-source adoption part of the team’s KPIs and introduce incentive programs. Recommended reading: Why Second Sourcing Matters: Real Challenges and Practical Solutions in Electronics Supply Chains.)

Anyone who has spent enough time in an electronics assembly factory knows that some key components simply have very long lead times—especially parts from strict Japanese suppliers. Lead times and prices are often “non-negotiable.” For example, MLCCs and connectors can have lead times of 40 to 80 days. But once you switch to Taiwanese or Chinese suppliers, lead times and prices drop quickly—along with the quality. Frustrating, but true.

From a business perspective, if Workingbear were the sole supplier of a component, it would usually mean that only I could make it, or that my capabilities were clearly better and my product quality was superior. In that case, I would control the pricing—just like Largan did when supplying camera lenses to Apple, or TPK in the early days of touch panels. But once another supplier can make a part with the same specifications, competition kicks in. Prices are forced down, or you simply lose the order.

In some cases, using alternative parts isn’t a choice—it’s a necessity, especially for long-life products. Component suppliers often announce EOL for parts like PMICs, DDR memory, or crystals. Sometimes there is no drop-in replacement, or the electrical specs may match but the package or lead configuration is different. When that happens, companies must quickly find another supplier or change the design to fit the new component.

So should second-source qualification be done? And when is the right time?

Workingbear believes that second-source qualification is an unavoidable “necessary evil” in manufacturing—and yes, it must be done. The key question is how to do it properly. In recent years, COVID-19-related border closures and rising geopolitical risks have increased awareness of supply chain diversification. As a result, second sourcing has become a required action for many large companies. Workingbear also believes the best timing for second-source qualification is during the final pilot run before a new product enters mass production, because:

-

At this stage, the product design is already mature, with few major design changes expected.

-

Second-source parts can be validated under the same conditions as the primary parts, reducing the risk of large differences.

-

Completing second-source validation during the R&D phase is the most efficient approach. Otherwise, the teams that take over later may not fully understand the original issues or know which points require special attention.

Supplier qualification for second sources is also a serious topic on its own. Choosing a supplier with poor quality control not only wipes out all the benefits of second sourcing, but can also cause product quality issues and even affect shipments. This is a topic for another day. In addition to evaluating quality systems, suppliers must also be assessed for technical capability. Take PCB suppliers as an example: their fine-pitch capability (3/3 mil, 2/2 mil), stack-up layer count, and HDI (High Density Interconnect) capability should all be clearly documented.

Of course, even if most second sources are qualified during the new product phase, there will always be a few that slip through. And it’s hard to predict exactly when a supplier will discontinue a part. That’s why new second-source requests will continue to pop up throughout the product’s life—unless the product itself reaches end of life.

Related Posts:

- What is the Electronic Components Spot Market (Buy and Sell)?

- Why a BOM (Bill of Materials) is Critical in Electronic Product Development

- Why Second Sourcing Matters: Real Challenges and Practical Solutions in Electronics Supply Chains

Leave a Reply