In electronics manufacturing and supply chain management, a “second source” (2nd source) means having an alternative supplier for critical components or materials. The goal is to spread risk and improve overall operations. It’s not just a safety net against supply disruptions—it’s also a way to stay competitive.

Many companies actively push for second-source adoption, and the reasons go far beyond cost control. Supply stability and flexibility are just as important. But if the benefits are so clear, why does implementation often run into trouble? Based on real-world experience in electronics manufacturing, this article looks at the benefits, the challenges, and practical strategies to help companies create a win-win outcome.

Why Do Supply Chains Like to Introduce a Second Source?

Supply chain managers are enthusiastic about second sources because they bring multiple benefits—especially in today’s world, where global supply chains are easily disrupted by geopolitics, pandemics, or natural disasters. Let’s look at two key aspects.

1. Risk Diversification and Supply Stability

Relying on a single supplier is often a hidden time bomb. When the original supplier faces capacity issues, part discontinuation (EOL, End of Life), or unexpected shortages, production lines can come to a standstill. A second source helps reduce these risks:

-

Handling shortages and EOL issues: Alternative parts are reviewed and approved in advance, allowing fast switching in emergencies and avoiding production downtime.

-

Shorter lead times: With multiple suppliers, orders can be split to reduce delay risks. For example, an import lead time of 40–80 days might be reduced to 20–60 days by adding local or diversified sources.

-

Better quality and stability: Second sourcing isn’t just a backup—it allows performance comparison between suppliers and the gradual elimination of poor performers, improving long-term quality.

In the 2025 supply chain environment, this is especially critical. The post-COVID chip shortage taught many companies to treat second sourcing as a standard practice. It’s often combined with ESG (Environmental, Social, and Governance) evaluations to avoid ethical or environmental risks tied to a single supplier.

2. Cost Optimization and Negotiation Power

Cost is always a hot topic. A second source isn’t just a backup—it can directly reduce costs:

-

Stronger negotiation leverage: Competition pushes original suppliers to lower prices and prevents monopolistic pricing.

-

Lower total cost: By shifting volume or using mixed sourcing strategies, companies can achieve material cost reductions and avoid extra costs caused by shortages.

-

Long-term financial benefits: Although upfront qualification requires investment, successful second sourcing can deliver 5–15% cost savings, directly improving profitability.

Because of these benefits, supply chain teams often see second sourcing as a “win-win” strategy that protects production and strengthens market competitiveness.

Common Challenges in Second-Source Implementation: The Root of the Vicious Cycle

Despite clear benefits, second-source projects often fall into a “vicious cycle” that discourages engineers and teams. Common pain points include:

-

Low engineer motivation: Second-source work is complex and time-consuming—spec reviews, pilot builds, and qualification testing—and is often seen as a “dirty job.” Engineers usually handle all validation work and are also blamed if production issues occur later, while the credit for cost savings often goes to procurement.

-

Cross-department conflicts: Coordination between R&D, engineering, and procurement is difficult. Misaligned KPIs lead to finger-pointing—for example, procurement focuses on price, while engineering worries about quality.

-

Quality and timing risks: Alternative parts may introduce spec differences or reliability issues (such as lower MTBF), or delay implementation. If not introduced at the right time—such as during pilot production—the cost of later changes can be much higher.

-

Outdated mindsets: Old experiences like “lower price means lower quality” still influence decisions, while modern tools such as AI-based supplier evaluation platforms are often overlooked.

If these issues aren’t addressed, second sourcing may not only fail but also increase risk—such as potential IP disputes or even new supply disruptions caused by poor design decisions.

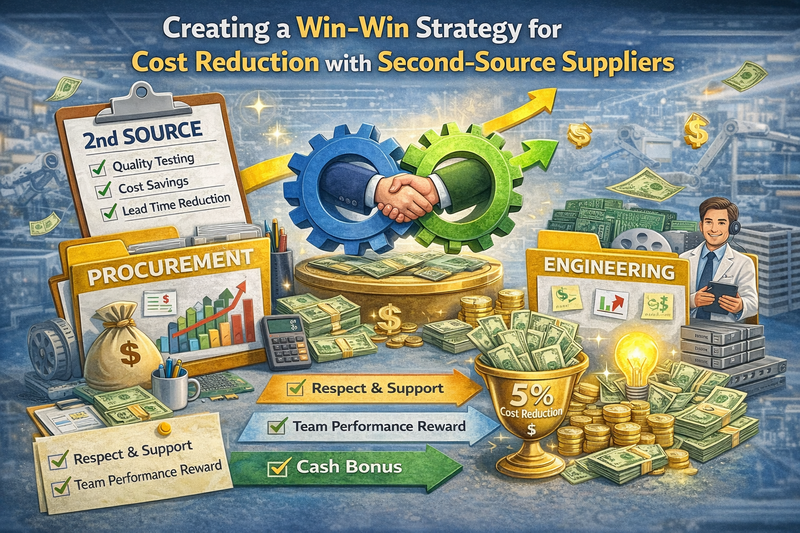

Optimization Strategies: Turning a Vicious Cycle into a Win-Win

To make second sourcing work, companies need changes in culture, process, and incentives. Here are three core strategies based on real-world practice:

Executive Support and Cross-Functional Collaboration

-

Senior management must actively lead and chair discussions to show commitment and give engineers confidence.

-

Create cross-functional teams and include second sourcing in the company roadmap, with regular progress tracking. Digital tools like ERP systems or AI platforms (such as SAP Ariba) can automate supplier evaluation and risk prediction.

Shared Credit and KPI Redesign

-

Include second-source results in team KPIs, such as “achieve three second-source conversions per year with a 5% material cost reduction target.”

-

Avoid letting one department take all the credit. Use a shared model: engineers handle qualification, procurement leads negotiations, and both share risks and recognition.

Incentives and Risk Management

-

Convert cost savings into bonuses—for example, 5–10% of total savings distributed to the team using a transparent formula (savings × contribution).

-

Strengthen risk management by performing FMEA (Failure Mode and Effects Analysis) before implementation, setting a three-month transition period and a rollback plan. The best timing is mid-development, with pilot builds to validate reliability across multiple models and avoid late-stage redesigns.

In addition, align with 2025 trends by integrating ESG audits and nearshoring strategies, selecting suppliers with lower carbon footprints, and using AI tools to monitor supply chain dynamics and prevent disruptions.

Conclusion: Start Small and Build a Second-Source Culture

Supply chains pursue second sources not blindly, but as a rational choice driven by risk management and cost optimization. To avoid falling into a vicious cycle, companies must balance benefits and challenges through executive support, proper incentives, and process optimization. A practical approach is to start with low-risk components or small parts and gradually build SOPs (Standard Operating Procedures). In today’s highly uncertain world, second sourcing is not just a tool—it’s a core element of business resilience. If you have related experience, feel free to share it so we can improve supply chain management together.

Related Posts:

Leave a Reply