As an engineer, Workingbear has to be honest—I really don’t like doing second-source qualification work. It’s time-consuming, stressful, and often thankless. If you do it well, management thinks it’s just part of your job. If it takes too long, they think you’re being difficult on purpose. And if any issue shows up later, they question your ability—“Why didn’t you catch this earlier?”

What frustrates engineers the most is this: after spending a huge amount of time and effort qualifying a second source or alternate part, once everything is approved, all the credit—cost savings, shorter lead times, stronger bargaining power—almost always goes to Procurement.

What engineers get instead is a line item in their work record, plus endless follow-up quality issues to deal with. No wonder engineers tend to avoid second-source projects whenever they can.

So the question is:

Is there any good way to make engineers more willing to participate in second-source qualification?

The answer is yes. It’s not that solutions don’t exist—it’s whether management is willing to take them seriously.

In another article, ”Why Does Second-Source Qualification Always Fall into a Vicious Cycle?”, Workingbear already explained that second sourcing is critical for a company and should be treated as a necessary mission.

Below are a few practical ways Workingbear believes can significantly increase engineers’ motivation.

First, engineers must feel that second-source qualification really matters.

This means top management must clearly show that second-source projects are important. At a minimum, a responsible manager should be assigned to lead the second-source review meetings.

Second-source teams are always cross-functional.

Having a manager who can lead the discussion, provide direction, and make final decisions gives the team a sense that their work is valued. It also helps resolve issues that engineers or PMs can’t decide on their own.

Management should not just “care in the background” without attending meetings—doing so greatly weakens the impact.

In reality, this manager only needs to spend about one hour per week hosting the meeting. The actual work is still done by engineers and PMs, but that leadership presence makes a big difference.

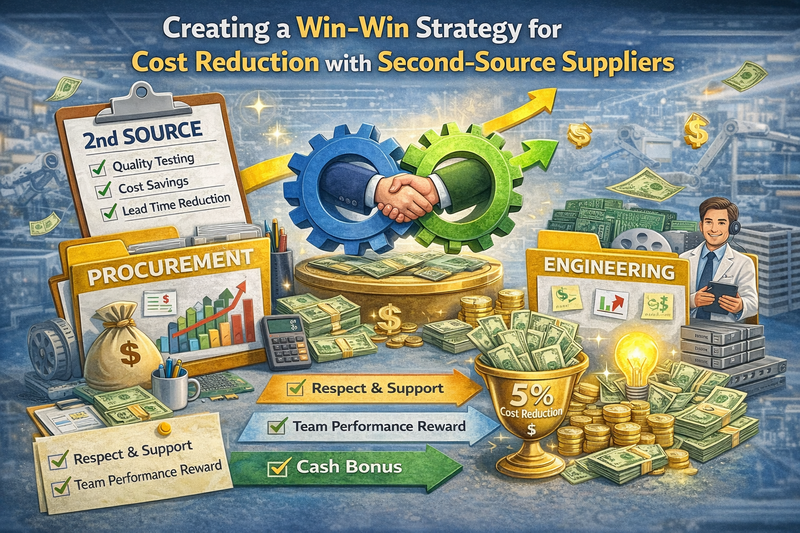

Second, all the credit from a successful second-source project must be shared.

Everyone involved should be able to count it as part of their performance.

Many companies include cost reduction targets in their annual KPIs, and second-source qualification is one of the most effective ways to achieve them.

Workingbear has seen many companies talk loudly about “cost reduction,” but very few actually execute it well.

After the slogan is announced, everything is pushed down to individual teams to figure out on their own—and often forgotten by year-end.

When there’s only talk and no action, employees quickly lose motivation.

This is why both cost reduction and second-source qualification often fail to gain real traction.

Third, consider sharing part of the cost savings as a bonus.

Money is a powerful motivator.

Once a second source is approved and fully implemented, the company can audit the annual forecasted savings and allocate a percentage of that amount as a team bonus.

If the reward is attractive, more people will be willing to invest their time and effort into second-source qualification.

Of course, a fair evaluation system and bonus cap must be defined.

And yes—where there are rewards, there should also be consequences.

If targets are not met, performance ratings should reflect that.

Related Posts:

Leave a Reply