Environmental Stress Screening (ESS) is a method used to apply certain environmental and operational stresses—such as power on/off cycles, bias voltage, pressure, thermal cycling, and vibration—to new or repaired products (usually electronics or components). The idea is to expose hidden early-failure issues that normal testing might miss. This helps weed out defective units and ensures better product quality.

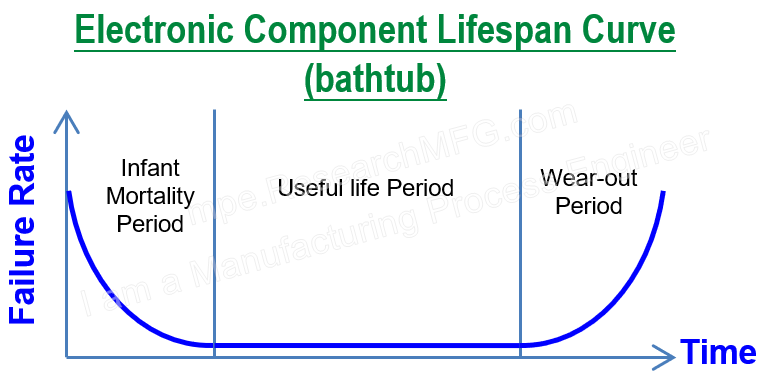

Looking at the bathtub curve (a typical reliability curve for electronics), we can divide a product’s life into three stages:

-

Infant Mortality Period – A high failure rate at the beginning, which quickly drops.

-

Useful Life Period – A long period of stable performance with a low and nearly constant failure rate.

-

Wear-Out Period – Failure rates increase again as parts age and wear out.

Failures during the infant mortality period are often due to poor design reliability, tolerance mismatches during assembly, or component compatibility issues. Once a product is running, mismatched or flawed units start to fail quickly. The stable middle phase is mainly affected by random environmental events, while the final phase sees failures due to aging parts.

The goal of ESS is to simulate the actual use environment and working conditions, so that products “get through” the infant mortality phase before reaching the customer. That way, when the customer starts using the product, it’s already in its stable, reliable phase.

How to Set Up ESS Properly

ESS testing should be tailored to the characteristics of the product or part. The stresses applied should match the real-world usage conditions. Long-term quality data is helpful when setting parameters. Be careful not to push the product beyond its actual capabilities—after all, these tested units will be delivered to customers. Too much stress could cause hidden damage or speed up aging, defeating the purpose.

Based on experience, common ESS tests for electronic assemblies include:

-

Repeated power on/off cycles

-

Temperature cycling (based on the product’s working environment and material limits)

-

Vibration (simulating shipping conditions by truck or boat)

For example, most engineering plastics shouldn’t be exposed to temperatures above 60°C for long periods—this can lead to brittleness or warping. Vibration tests should simulate real-life transport conditions.

Is ESS Still Necessary Today?

Honestly, with today’s advanced design and manufacturing processes, most commercial electronic components no longer experience high failure rates during the early stages of life. Thanks to solid MTBF (Mean Time Between Failures) calculations and strong quality controls, ESS has become less common for general consumer products where safety isn’t a major concern.

Of course, this is just something Workingbear has observed. You might have your own experiences or insights—and that’s totally okay!

Related posts:

Leave a Reply